Annular Cutters

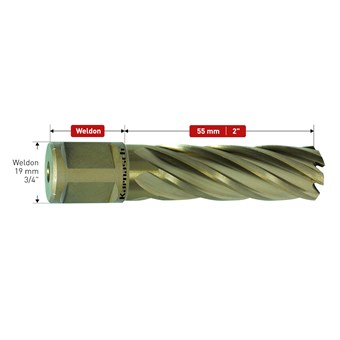

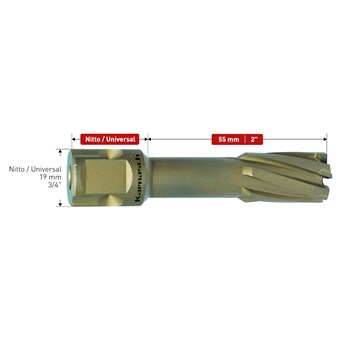

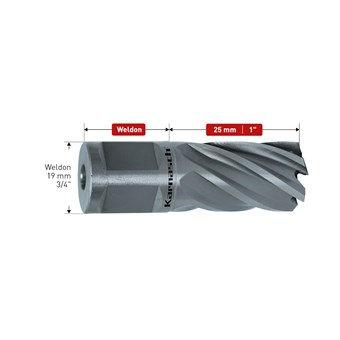

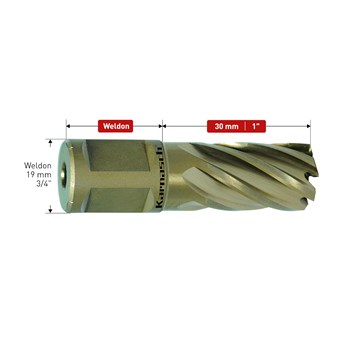

Karnasch Professional Tools presents a wide range of high performance drills for your individual purposes. Choose from a range of annular cutters, rail cutters and twist drills, in carbide-tipped, HSS-XE steel or Powder steel. Possible shanks are Weldon shank, Nitto shank, Universal shank or Fein-Quick-In shank. Karnasch Premium drills guarantee smooth and easy machining of almost all types of steel, including extremely machinable materials and rail steels.Premium Karnasch annular cutters, rail cutters and twist drills

Karnasch drills offer the optimum price-performance ratio for the machining of almost all materials

Karnasch Professional Tools presents a wide range of high performance drills for your individual purposes. Choose from a range of annular cutters, rail cutters and twist drills, in carbide-tipped, HSS-XE steel or Powder steel. Possible shanks are Weldon shank, Nitto shank, Universal shank or Fein-Quick-In shank.

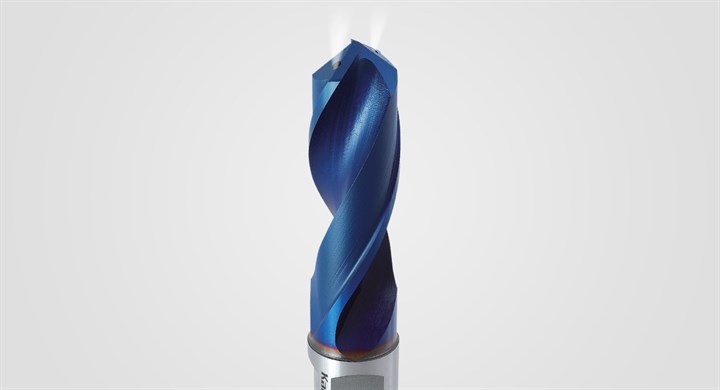

Karnasch Premium drills guarantee smooth and easy machining of almost all types of steel, including extremely machinable materials and rail steels. For optimal machining, maximum tool life and best heat protection, you can rely on Karnasch drills.

Our annular cutters are available in diameters from 8 mm up to 200 mm. Our rail cutters are available in diameters from 6 mm up to 60 mm. Twist drills for general steel machining are available in diameters from 2.5 mm up to 12 mm.

New

Discover Carbide Tipped

Discover HSS-XE / Powder Steel

Discover Rail Cutters

Discover Twist Drills

Discover HSS-CO Twist Drills

The Karnasch Core Drill, Rail Drill and Twist Drill range - state of the art technology