Solid Carbide Thread Mills

Premium spiral fluted solid carbide thread mills for internal threads with and without internal cooling. The Karnasch solid carbide thread mills enable the production of threads in steel as well as in abrasive materials. In sizes from M 3 to M 12, with a diamond coating, a 30 degree spiral and an additional countersinking step, the thread mills can be used for the machining of graphite and GRP/CRP.Solid carbide thread mills

Premium spiral fluted solid carbide thread mills for internal threads with and without internal cooling. The Karnasch solid carbide thread mills enable the production of threads in steel as well as in abrasive materials.In sizes from M 3 to M 12, with a diamond coating, a 30° spiral and an additional countersinking step, the thread mills can be used for the machining of graphite and GRP/CRP.

Due to the special coating for steel processing up to 70 HRC, logarithmic relief grinding and tool cooling, the thread mills from M3 to M8 are the best choice for achieving outstanding tool lives (available from August 1, 2019).

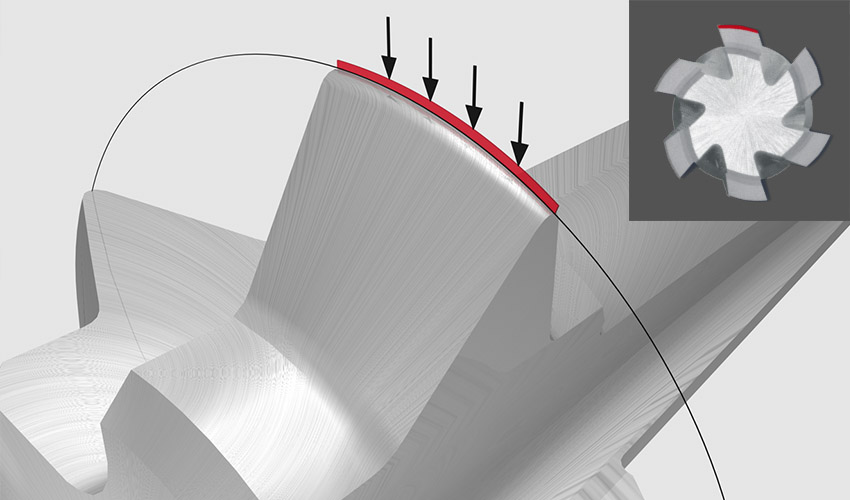

The combination of logarithmic relief grinding, internal coolant supply and cooling leaks at each cutting edge increases the process reliability and tool life of the solid carbide thread mills considerably.

1 3 Results

Karnasch Thread Mills -

the new standard for threading

Excellent qualities for challenging manufacturing processes

The solid carbide thread mills by Karnasch for threading in steel have a specially matched coating that contribute to an excellent surface finish and an outstanding wear resistance.

Due to the special profile shape the thread remains true to size, distortion-free and is shaped optimally.

The process reliable chip removal is controlled by specially developed cutting edge geometries. The internal coolant supply and the cooling channel outlets at each cutting edge increase process reliability and service life considerably.

The Karnasch range of threading tools also includes solid carbide whirling thread cutters, solid carbide taps and HSS-Co taps.