- Home

- |

- Products

- |

- Drilling

- |

- Step Drills, Tube & Sheet Drills

- |

- 3 Piece Set, step drills, HSS-XE BLUE-DUR coated, 3 cutting edges

3 Piece Set, step drills, HSS-XE BLUE-DUR coated, 3 cutting edges

Product Description

The Karnasch Professional step drill made of HSS-XE steel and TiN-GOLD coating and spiral fluted with split point

Karnasch STEP DRILLS are designed to drill perfectly round holes in sheet metals of an thickness 4 - 5 mm. The transition from one step to the next perfectly deburrs the previously drilled hole. Step drills are therefore a drilling and deburring tool combination.

This versatile tool combines several drills with diameters of 4 - 30 mm. The radius transition simultaneously bezels or deburrs the bore holes.

The drills are axial-radially relief grounded and can be resharpened at the tooth face.

HSS-XE steel + TiN-GOLD coating

Made of high-alloyed special steel XE for considerably longer service life than HSS-Steel. TiN-GOLD coating for a further substantial increase in service life also when machining dry (no/little cooling).

CONTENT:

3 step drills HSS-XE + TiN-GOLD coated:

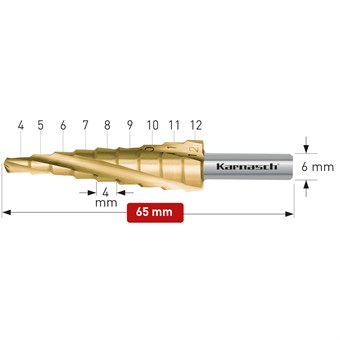

step drills, Diameter 4 - 12 mm

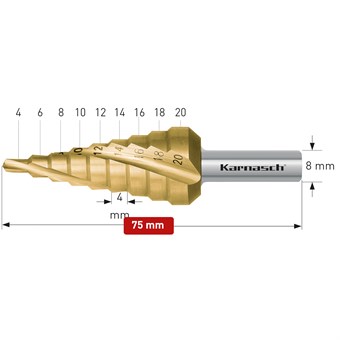

step drills, Diameter 4 - 20 mm

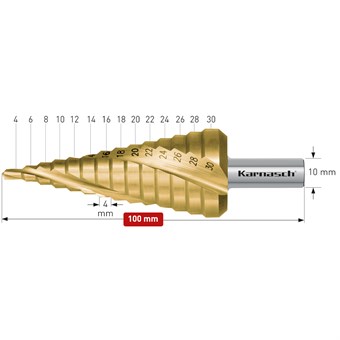

step drills, Diameter 6 - 30 mm

3-Flat shank for:

- Excellent torque transmission

- No slippage in the drill chuck

- This results to superior cutting output

All step drills and sheets drills are available in the patented BLUE-DUR-coating or TiN-GOLD-coating. Coatings significantly increase the service life. Strongly recommended for difficult materials such as stainless steels and if drilling without coolants.

All step drills and sheet drills comes lasered with diameters in the spiral.

All step drills and sheet drills are made of high-alloy steel HSS-XE for a hardness up to 68 HRC. This results in high wear resistance and service life.

Step drills and sheet drills are also available spiral-fluted for:

- Smooth cutting behavior

- No sticking in the material

- Low cutting forces

- Less burrs on the work piece

- Longer service life

TiN-Gold Coating

For considerably longer tool life in all types of steel for wet and dry machining.

- Coating technology: PVD

- Micro hardness: 2700 HV0.05

- Coating material: TiN

- Coating thickness: Diameter-related

- Max. operating temperature: 600 degrees C

This optimized TiN gold coating provides for a substantial increase of tool life. Due to its high hardness and low coefficient of friction, significant tool life increases are achieved even with dry machining (without/with little cooling).

Product Downloads

There are no download types with downloads for this product.