- Home

- |

- Products

- |

- Milling

- |

- Solid Carbide End Mills

- |

- Solid Carbide Miniature End Mill, Ball Nose, <20xD depth, <55 HRC

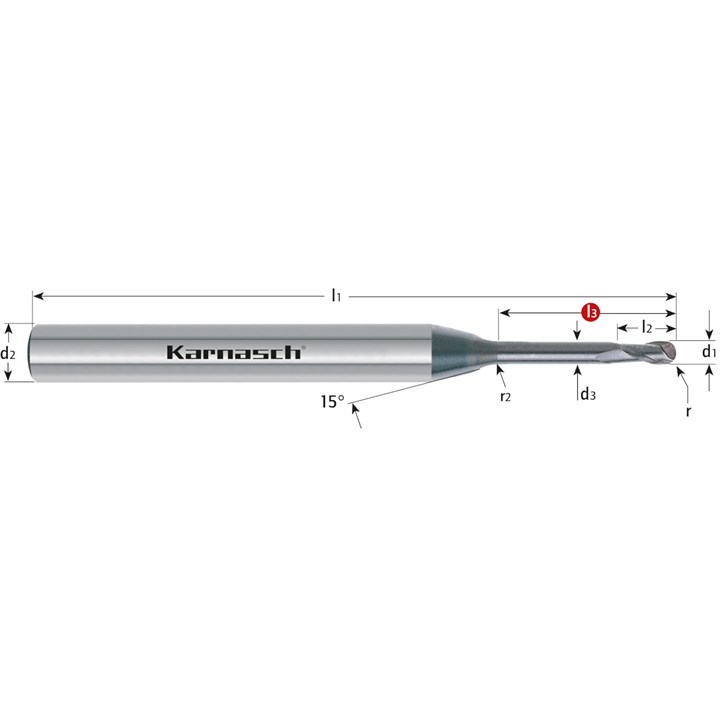

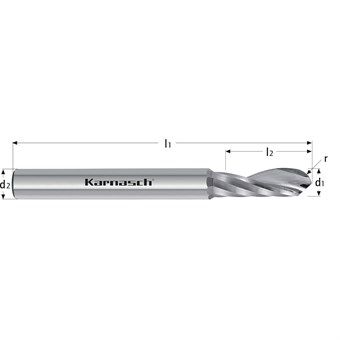

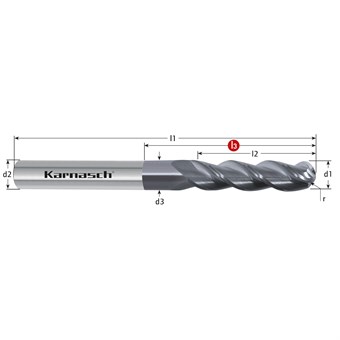

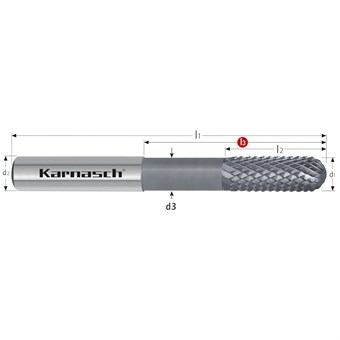

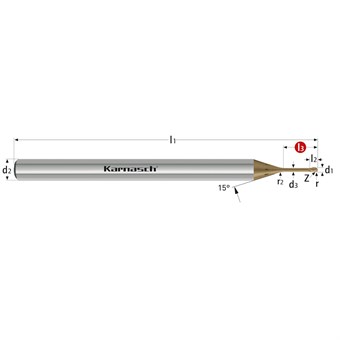

Solid Carbide Miniature End Mill, Ball Nose, <20xD depth, <55 HRC

308012_P

More details on catalogue page number 52 -

Click to view

£0.00

From £37.98 Excl VAT

(£45.20 incl VAT)

Live prices currently unavailable, list price shown.

Solid carbide miniature end mill, ball nose, <20xd depth, <55 hrc.

Product Description

Solid Carbide Miniature End Mill, Ball Nose, <20xD depth, <55 HRC.

WRC² Coating

For milling of steel up to 55 HRC.

- Coating technology: Sputtering

- Micro hardness: 3700 HV0.05

- Coating material: AlTin

- Coating thickness: Diameter-related

- Max. operating temperature: 1000 degrees C

The WRC² coating was specially developed for the machining of materials up to 55 HRC. The increased aluminum content contributes to better temperature stability and makes WRC² the first choice for the machining of steels and castings up to 55HRC in both wet and dry machining.

Product Downloads

There are no download types with downloads for this product.

Related Products

No related products

Alternative Products

3062600030

Solid carbide minature ball nose slot mill, <15xd diameter cutting depth, shank 4mm.

£102.36 Excl VAT

291658_P

Solid carbide one-tooth end mill with corner radius, right spiral, right cutting, mirror finish.

From £78.59 Excl VAT

306523_P

Pcd extreme 3d ball miling cutter, hsc high-speed-cutting.

From £341.85 Excl VAT

306574_P

Graphite roughing end mill for large working depths with 3d ball nose end mill.

From £117.11 Excl VAT

306592_P

Roughing end mill <7xd cutting depth , hsc.

From £96.57 Excl VAT

306633_P

Cbn high-end micro end mill < 10xd cutting depth, shank 6mm.

From £86.90 Excl VAT

306259_P

Solid carbide miniature ball nose mill, with interior cooling holes in shank, shank 4mm.

From £99.93 Excl VAT

Product Code

D1 (mm)

D2 (mm)

D3 (mm)

L3 (mm)

Radius

L2 (mm)

L1 (mm)

Coating

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

Metric / Imp.

Shank Angle

Version

Z (Cutting Edges)

Product Code

3080120020005

IN STOCK

D1 (mm)

0,2

D2 (mm)

4

D3 (mm)

0,18

L3 (mm)

0,5

Radius

0,1

L2 (mm)

0,2

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

0,68

Incline Angle 1.0

0,71

Incline Angle 2.0

0,77

Incline Angle 3.0

0,83

Cone Neck Angle

1

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012002001

IN STOCK

D1 (mm)

0,2

D2 (mm)

4

D3 (mm)

0,18

L3 (mm)

1

Radius

0,1

L2 (mm)

0,2

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

1,2

Incline Angle 1.0

1,25

Incline Angle 2.0

1,34

Incline Angle 3.0

1,45

Cone Neck Angle

1

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012003001

IN STOCK

D1 (mm)

0,3

D2 (mm)

4

D3 (mm)

0,28

L3 (mm)

1

Radius

0,15

L2 (mm)

0,25

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

1,29

Incline Angle 1.0

1,37

Incline Angle 2.0

1,49

Incline Angle 3.0

1,62

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012003002

IN STOCK

D1 (mm)

0,3

D2 (mm)

4

D3 (mm)

0,28

L3 (mm)

2

Radius

0,15

L2 (mm)

0,25

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

2,35

Incline Angle 1.0

2,46

Incline Angle 2.0

2,65

Incline Angle 3.0

2,86

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012003003

IN STOCK

D1 (mm)

0,3

D2 (mm)

4

D3 (mm)

0,28

L3 (mm)

3

Radius

0,15

L2 (mm)

0,25

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

3,4

Incline Angle 1.0

3,53

Incline Angle 2.0

3,8

Incline Angle 3.0

4,1

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012004002

IN STOCK

D1 (mm)

0,4

D2 (mm)

4

D3 (mm)

0,38

L3 (mm)

2

Radius

0,2

L2 (mm)

0,3

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

2,35

Incline Angle 1.0

2,46

Incline Angle 2.0

2,65

Incline Angle 3.0

2,86

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012004003

IN STOCK

D1 (mm)

0,4

D2 (mm)

4

D3 (mm)

0,38

L3 (mm)

3

Radius

0,2

L2 (mm)

0,3

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

3,4

Incline Angle 1.0

3,53

Incline Angle 2.0

3,8

Incline Angle 3.0

4,1

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012004004

IN STOCK

D1 (mm)

0,4

D2 (mm)

4

D3 (mm)

0,38

L3 (mm)

4

Radius

0,2

L2 (mm)

0,3

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

4,44

Incline Angle 1.0

4,6

Incline Angle 2.0

4,95

Incline Angle 3.0

5,35

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012005002

IN STOCK

D1 (mm)

0,5

D2 (mm)

4

D3 (mm)

0,48

L3 (mm)

2

Radius

0,25

L2 (mm)

0,4

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

2,35

Incline Angle 1.0

2,46

Incline Angle 2.0

2,65

Incline Angle 3.0

2,86

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012005003

IN STOCK

D1 (mm)

0,5

D2 (mm)

4

D3 (mm)

0,48

L3 (mm)

3

Radius

0,25

L2 (mm)

0,4

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

3,4

Incline Angle 1.0

3,53

Incline Angle 2.0

3,8

Incline Angle 3.0

4,1

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012005004

IN STOCK

D1 (mm)

0,5

D2 (mm)

4

D3 (mm)

0,48

L3 (mm)

4

Radius

0,25

L2 (mm)

0,4

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

4,44

Incline Angle 1.0

4,6

Incline Angle 2.0

4,95

Incline Angle 3.0

5,35

Cone Neck Angle

2

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012006002

IN STOCK

D1 (mm)

0,6

D2 (mm)

4

D3 (mm)

0,58

L3 (mm)

2

Radius

0,3

L2 (mm)

0,5

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

2,5

Incline Angle 1.0

2,67

Incline Angle 2.0

2,94

Incline Angle 3.0

3,19

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012006003

IN STOCK

D1 (mm)

0,6

D2 (mm)

4

D3 (mm)

0,58

L3 (mm)

3

Radius

0,3

L2 (mm)

0,5

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

3,57

Incline Angle 1.0

3,78

Incline Angle 2.0

4,1

Incline Angle 3.0

4,43

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012006004

IN STOCK

D1 (mm)

0,6

D2 (mm)

4

D3 (mm)

0,58

L3 (mm)

4

Radius

0,3

L2 (mm)

0,5

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

4,63

Incline Angle 1.0

4,87

Incline Angle 2.0

5,25

Incline Angle 3.0

5,67

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012006006

IN STOCK

D1 (mm)

0,6

D2 (mm)

4

D3 (mm)

0,58

L3 (mm)

6

Radius

0,3

L2 (mm)

0,5

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

6,74

Incline Angle 1.0

7,02

Incline Angle 2.0

7,55

Incline Angle 3.0

8,16

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012006008

IN STOCK

D1 (mm)

0,6

D2 (mm)

4

D3 (mm)

0,58

L3 (mm)

8

Radius

0,3

L2 (mm)

0,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,83

Incline Angle 1.0

9,16

Incline Angle 2.0

9,85

Incline Angle 3.0

10,65

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008002

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

2

Radius

0,4

L2 (mm)

0,6

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

2,54

Incline Angle 1.0

2,7

Incline Angle 2.0

2,97

Incline Angle 3.0

3,21

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008004

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

4

Radius

0,4

L2 (mm)

0,6

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

4,67

Incline Angle 1.0

4,89

Incline Angle 2.0

5,27

Incline Angle 3.0

5,7

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008005

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

5

Radius

0,4

L2 (mm)

0,6

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

5,72

Incline Angle 1.0

5,97

Incline Angle 2.0

6,42

Incline Angle 3.0

6,94

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008006

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

6

Radius

0,4

L2 (mm)

0,6

L1 (mm)

45

Coating

AlTiN/WRC2

Incline Angle 0.5

6,77

Incline Angle 1.0

7,04

Incline Angle 2.0

7,57

Incline Angle 3.0

8,18

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008008

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

8

Radius

0,4

L2 (mm)

0,6

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,85

Incline Angle 1.0

9,18

Incline Angle 2.0

9,87

Incline Angle 3.0

10,67

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012008010

IN STOCK

D1 (mm)

0,8

D2 (mm)

4

D3 (mm)

0,77

L3 (mm)

10

Radius

0,4

L2 (mm)

0,6

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

10,93

Incline Angle 1.0

11,32

Incline Angle 2.0

12,17

Incline Angle 3.0

13,16

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010003

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

3

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

3,67

Incline Angle 1.0

3,85

Incline Angle 2.0

4,16

Incline Angle 3.0

4,5

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010004

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

4

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

4,72

Incline Angle 1.0

4,94

Incline Angle 2.0

5,31

Incline Angle 3.0

5,74

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010005

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

5

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

5,77

Incline Angle 1.0

6,01

Incline Angle 2.0

6,46

Incline Angle 3.0

6,99

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010006

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

6

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

6,82

Incline Angle 1.0

7,08

Incline Angle 2.0

7,61

Incline Angle 3.0

8,23

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010007

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

7

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

7,86

Incline Angle 1.0

8,15

Incline Angle 2.0

8,76

Incline Angle 3.0

9,47

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010008

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

8

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,9

Incline Angle 1.0

9,22

Incline Angle 2.0

9,91

Incline Angle 3.0

10,72

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010010

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

10

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

10,98

Incline Angle 1.0

11,36

Incline Angle 2.0

12,21

Incline Angle 3.0

13,2

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010012

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

12

Radius

0,5

L2 (mm)

0,8

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

13,04

Incline Angle 1.0

13,5

Incline Angle 2.0

14,51

Incline Angle 3.0

15,69

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010015

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

15

Radius

0,5

L2 (mm)

0,8

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,15

Incline Angle 1.0

16,71

Incline Angle 2.0

17,96

Incline Angle 3.0

19,42

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012010020

IN STOCK

D1 (mm)

1

D2 (mm)

4

D3 (mm)

0,95

L3 (mm)

20

Radius

0,5

L2 (mm)

0,8

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,31

Incline Angle 1.0

22,06

Incline Angle 2.0

23,71

Incline Angle 3.0

25,63

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012012005

IN STOCK

D1 (mm)

1,2

D2 (mm)

4

D3 (mm)

1,15

L3 (mm)

5

Radius

0,6

L2 (mm)

1

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

5,77

Incline Angle 1.0

6,01

Incline Angle 2.0

6,46

Incline Angle 3.0

6,99

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012012006

IN STOCK

D1 (mm)

1,2

D2 (mm)

4

D3 (mm)

1,15

L3 (mm)

6

Radius

0,6

L2 (mm)

1

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

6,82

Incline Angle 1.0

7,08

Incline Angle 2.0

7,61

Incline Angle 3.0

8,23

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012012008

IN STOCK

D1 (mm)

1,2

D2 (mm)

4

D3 (mm)

1,15

L3 (mm)

8

Radius

0,6

L2 (mm)

1

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,9

Incline Angle 1.0

9,22

Incline Angle 2.0

9,91

Incline Angle 3.0

10,72

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012012010

IN STOCK

D1 (mm)

1,2

D2 (mm)

4

D3 (mm)

1,15

L3 (mm)

10

Radius

0,6

L2 (mm)

1

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

10,98

Incline Angle 1.0

11,36

Incline Angle 2.0

12,21

Incline Angle 3.0

13,2

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012012012

IN STOCK

D1 (mm)

1,2

D2 (mm)

4

D3 (mm)

1,15

L3 (mm)

12

Radius

0,6

L2 (mm)

1

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

13,04

Incline Angle 1.0

13,5

Incline Angle 2.0

14,51

Incline Angle 3.0

15,69

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015006

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

6

Radius

0,75

L2 (mm)

1,2

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

6,84

Incline Angle 1.0

7,1

Incline Angle 2.0

7,63

Incline Angle 3.0

8,25

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015008

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

8

Radius

0,75

L2 (mm)

1,2

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,92

Incline Angle 1.0

9,24

Incline Angle 2.0

9,93

Incline Angle 3.0

10,74

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015010

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

10

Radius

0,75

L2 (mm)

1,2

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11

Incline Angle 1.0

11,38

Incline Angle 2.0

12,23

Incline Angle 3.0

13,23

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015012

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

12

Radius

0,75

L2 (mm)

1,2

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

13,06

Incline Angle 1.0

13,52

Incline Angle 2.0

14,53

Incline Angle 3.0

15,71

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015015

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

15

Radius

0,75

L2 (mm)

1,2

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,17

Incline Angle 1.0

16,73

Incline Angle 2.0

17,98

Incline Angle 3.0

19,44

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012015020

IN STOCK

D1 (mm)

1,5

D2 (mm)

4

D3 (mm)

1,44

L3 (mm)

20

Radius

0,75

L2 (mm)

1,2

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,33

Incline Angle 1.0

22,08

Incline Angle 2.0

23,73

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020006

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

6

Radius

1

L2 (mm)

1,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

6,89

Incline Angle 1.0

7,14

Incline Angle 2.0

7,68

Incline Angle 3.0

8,3

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020008

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

8

Radius

1

L2 (mm)

1,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

8,97

Incline Angle 1.0

9,28

Incline Angle 2.0

9,98

Incline Angle 3.0

10,79

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020010

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

10

Radius

1

L2 (mm)

1,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11,04

Incline Angle 1.0

11,42

Incline Angle 2.0

12,28

Incline Angle 3.0

13,27

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020012

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

12

Radius

1

L2 (mm)

1,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

13,1

Incline Angle 1.0

13,56

Incline Angle 2.0

14,58

Incline Angle 3.0

15,76

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020015

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

15

Radius

1

L2 (mm)

1,5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,2

Incline Angle 1.0

16,77

Incline Angle 2.0

18,03

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020020

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

20

Radius

1

L2 (mm)

1,5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,37

Incline Angle 1.0

22,12

Incline Angle 2.0

23,77

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020025

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

25

Radius

1

L2 (mm)

1,5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

26,54

Incline Angle 1.0

27,47

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012020030

IN STOCK

D1 (mm)

2

D2 (mm)

4

D3 (mm)

1,92

L3 (mm)

30

Radius

1

L2 (mm)

1,5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

31,71

Incline Angle 1.0

32,81

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012025010

IN STOCK

D1 (mm)

2,5

D2 (mm)

4

D3 (mm)

2,4

L3 (mm)

10

Radius

1,25

L2 (mm)

2,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11,07

Incline Angle 1.0

11,46

Incline Angle 2.0

12,32

Incline Angle 3.0

13,32

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012025015

IN STOCK

D1 (mm)

2,5

D2 (mm)

4

D3 (mm)

2,4

L3 (mm)

15

Radius

1,25

L2 (mm)

2,5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,24

Incline Angle 1.0

16,81

Incline Angle 2.0

18,07

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030005

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

5

Radius

1,5

L2 (mm)

2,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

6,1

Incline Angle 1.0

6,31

Incline Angle 2.0

6,78

Incline Angle 3.0

7,33

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030010

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

10

Radius

1,5

L2 (mm)

2,5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11,27

Incline Angle 1.0

11,66

Incline Angle 2.0

12,53

Incline Angle 3.0

13,55

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030015

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

15

Radius

1,5

L2 (mm)

2,5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,44

Incline Angle 1.0

17,01

Incline Angle 2.0

18,28

Incline Angle 3.0

19,77

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030020

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

20

Radius

1,5

L2 (mm)

2,5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,6

Incline Angle 1.0

22,36

Incline Angle 2.0

24,03

Incline Angle 3.0

25,98

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030025

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

25

Radius

1,5

L2 (mm)

2,5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

26,77

Incline Angle 1.0

27,7

Incline Angle 2.0

29,78

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012030030

IN STOCK

D1 (mm)

3

D2 (mm)

6

D3 (mm)

2,9

L3 (mm)

30

Radius

1,5

L2 (mm)

2,5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

31,94

Incline Angle 1.0

33,05

Incline Angle 2.0

35,53

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012040010

IN STOCK

D1 (mm)

4

D2 (mm)

6

D3 (mm)

3,9

L3 (mm)

10

Radius

2

L2 (mm)

3,2

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11,07

Incline Angle 1.0

11,46

Incline Angle 2.0

12,32

Incline Angle 3.0

13,32

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012040015

IN STOCK

D1 (mm)

4

D2 (mm)

6

D3 (mm)

3,9

L3 (mm)

15

Radius

2

L2 (mm)

3,2

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,24

Incline Angle 1.0

16,81

Incline Angle 2.0

18,07

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012040020

IN STOCK

D1 (mm)

4

D2 (mm)

6

D3 (mm)

3,9

L3 (mm)

20

Radius

2

L2 (mm)

3,2

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,41

Incline Angle 1.0

22,16

Incline Angle 2.0

23,82

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012040025

IN STOCK

D1 (mm)

4

D2 (mm)

6

D3 (mm)

3,9

L3 (mm)

25

Radius

2

L2 (mm)

3,2

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

26,58

Incline Angle 1.0

27,5

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012040030

IN STOCK

D1 (mm)

4

D2 (mm)

6

D3 (mm)

3,9

L3 (mm)

30

Radius

2

L2 (mm)

3,2

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

31,75

Incline Angle 1.0

32,85

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050010

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

10

Radius

2,5

L2 (mm)

4

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

11,27

Incline Angle 1.0

11,66

Incline Angle 2.0

12,53

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050015

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

15

Radius

2,5

L2 (mm)

4

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

16,44

Incline Angle 1.0

17,01

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050020

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

20

Radius

2,5

L2 (mm)

4

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

21,6

Incline Angle 1.0

22,36

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050025

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

25

Radius

2,5

L2 (mm)

4

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

26,77

Incline Angle 1.0

27,7

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050030

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

30

Radius

2,5

L2 (mm)

4

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

31,94

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012050040

IN STOCK

D1 (mm)

5

D2 (mm)

6

D3 (mm)

4,9

L3 (mm)

40

Radius

2,5

L2 (mm)

4

L1 (mm)

80

Coating

AlTiN/WRC2

Incline Angle 0.5

42,28

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060010

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

10

Radius

3

L2 (mm)

5

L1 (mm)

50

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060015

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

15

Radius

3

L2 (mm)

5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060020

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

20

Radius

3

L2 (mm)

5

L1 (mm)

60

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060025

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

25

Radius

3

L2 (mm)

5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060030

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

30

Radius

3

L2 (mm)

5

L1 (mm)

70

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2

Product Code

308012060040

IN STOCK

D1 (mm)

6

D2 (mm)

6

D3 (mm)

5,9

L3 (mm)

40

Radius

3

L2 (mm)

5

L1 (mm)

80

Coating

AlTiN/WRC2

Incline Angle 0.5

Incline Angle 1.0

Incline Angle 2.0

Incline Angle 3.0

Cone Neck Angle

4

Metric / Imp.

Metric

Shank Angle

15

Version

Slot Cutters

Z (Cutting Edges)

2