- Home

- |

- Products

- |

- Milling

- |

- Solid Carbide End Mills

- |

- Solid Carbide Profile End Mill, Forward/Backward Removal

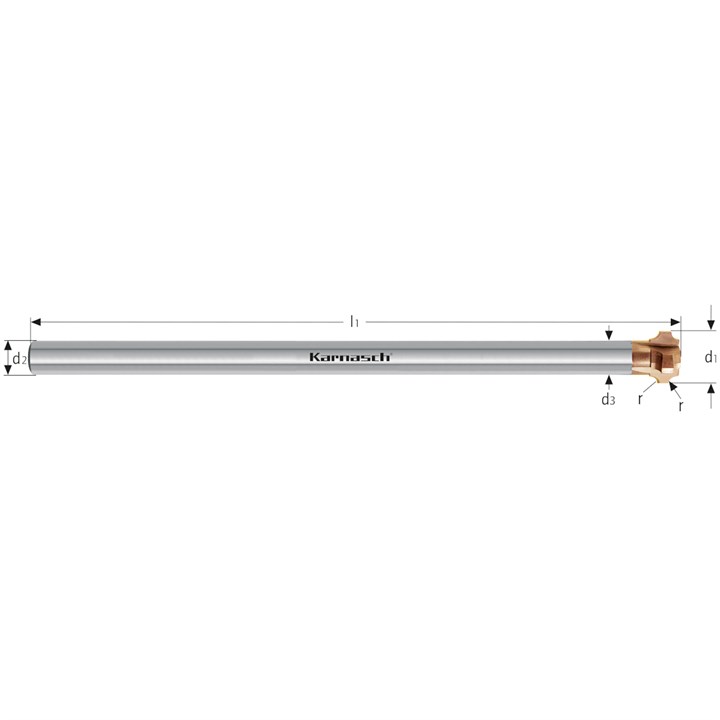

Solid Carbide Profile End Mill, Forward/Backward Removal

306490_P

More details on catalogue page number 106 - Click to view

From £255.83 Excl VAT (£304.44 incl VAT)

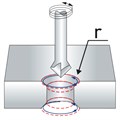

Solid carbide forward- and backward quatercicle, profile end mill.

Product Description

Solid carbide forward- and backward quatercicle, profile end mill.

HXC-NANO³ Coating

For the machining of hardened steels up to 70 HRC / stainless steels and titanium.

- Coating technology: Sputtering

- Micro hardness: 3800 HV0.05

- Coating material: TiAlN/TiSiN based

- Coating thickness: Diameter-related

- Max. operating temperature: 1100 degrees C

The silicon doping gives HXC-Nano³ a particularly high hardness and oxidation resistance. The special coating process achieves very smooth surfaces and improved coating adhesion, which are ideal for the machining of hardened steels, stainless steels or titanium.

Product Downloads

There are no download types with downloads for this product.