Countersinks

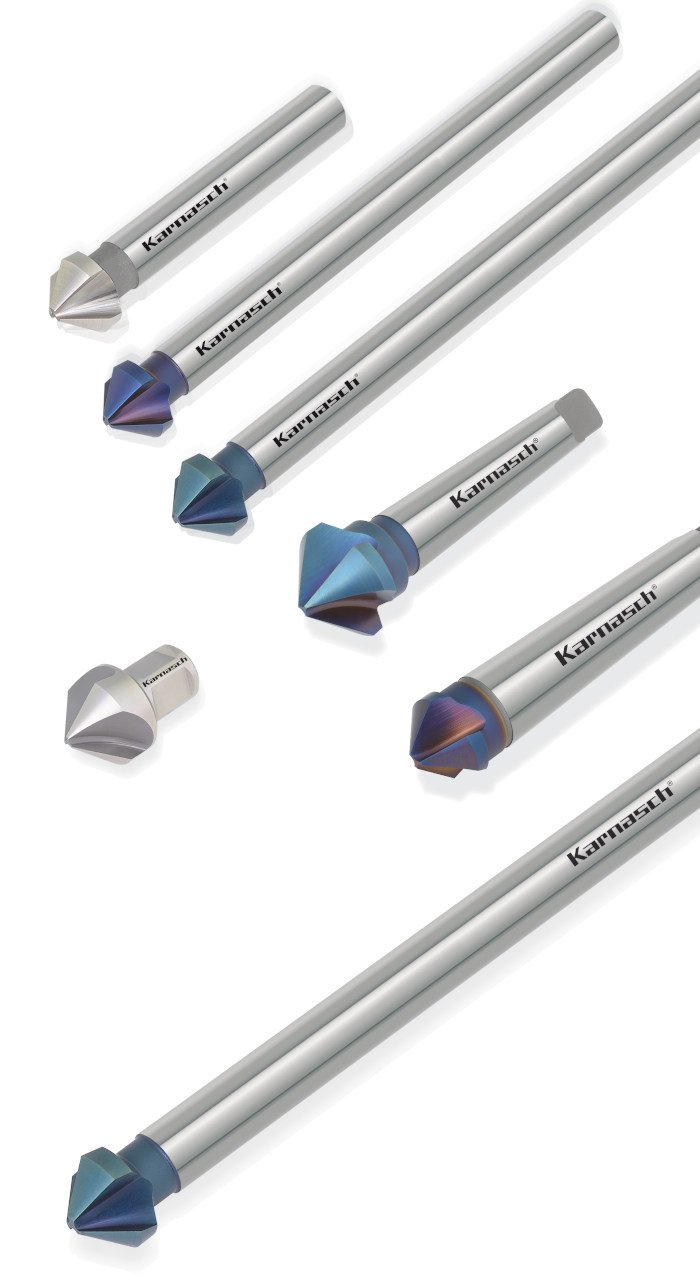

Countersinks belong to the standard products in the tool industry. Almost no drilling takes place without sinking. Countersinking is used for secondary machining of the materials and provides them with the final surface finish. That is why Karnasch relies on the highest quality and the latest tool technologies for countersinking. Karnasch countersinks are available in different designs for every application. The special BLUE-TEC tool coating makes the countersinks by Karnasch additionally unique.Karnasch countersinks for the machining of steel, cast iron, non-ferrous and light metals, stainless and acid-resistant steels and titanium alloys on CNC machines

Countersinks belong to the standard products in the tool industry. Almost no drilling takes place without sinking. Countersinking is used for secondary machining of the materials and provides them with the final surface finish. That is why Karnasch relies on the highest quality and the latest tool technologies for countersinking. Karnasch countersinks are available in different designs for every application. The special BLUE-TEC tool coating makes the countersinks by Karnasch additionally unique.

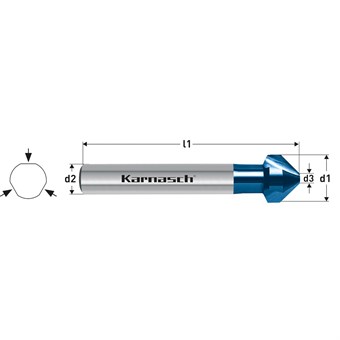

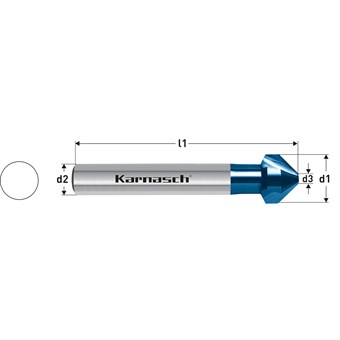

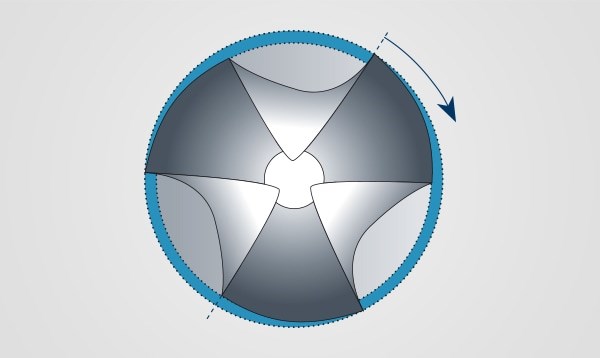

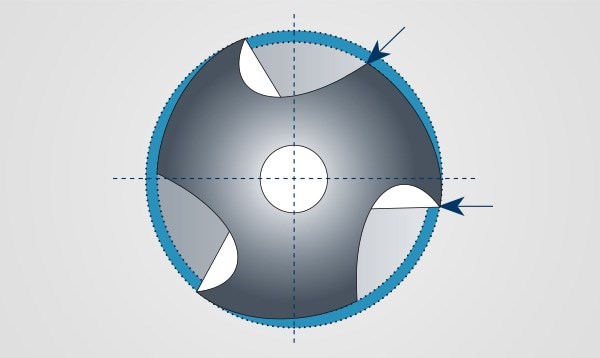

Karnasch Professional Tools countersinks are available in HSS-XE, ASP powder steel, solid carbide- and carbide-tipped types, with diameters from 4.3 mm to 80 mm. The special BLUE-TEC tool coating significantly increases surface hardness and tool life. CBN deep-ground flutes enables nearly burr- and chatter-free countersinking.

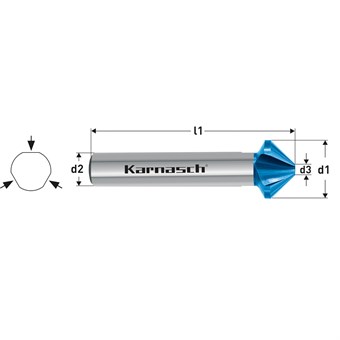

Due to the wide range of countersinks, nearly all steels that are difficult to process (such as stainless and acid-resistant steels), titanium and titanium alloys, light metals and other types of steel, can be machined. The cutting edge geometry of the countersinks has been optimized especially for automatic and rapid feed, enabling up to 30% faster countersinking and up to 40% longer tool life (RAPID-CUT version).

Various applications in many different industries

Countersinks for machining of steel, stainless steel, cast iron, non-ferrous and light metals

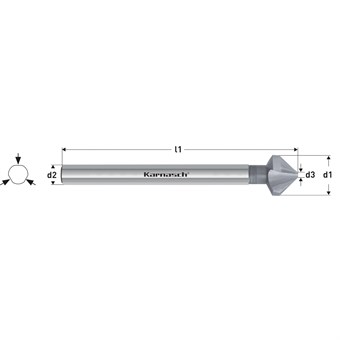

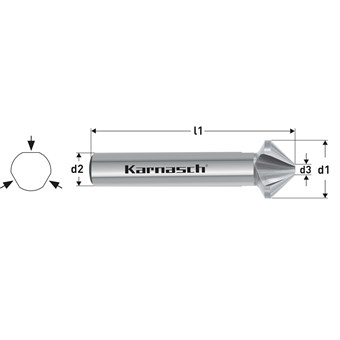

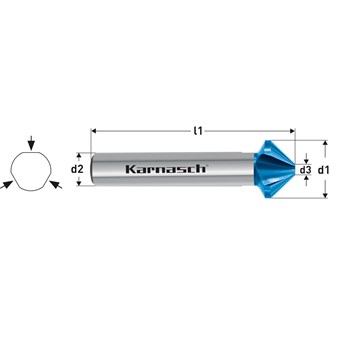

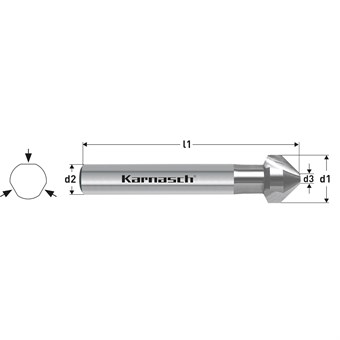

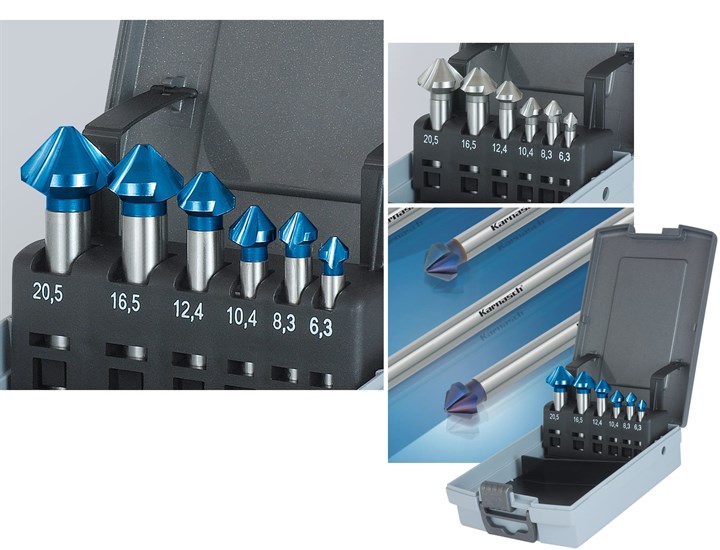

- Different quality stages (HSS-XE, carbide-tipped, ASP powder steel and carbide)

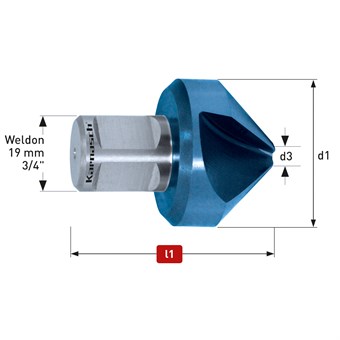

- Different shank types (cylindrical, Weldon and 3 surface shank)

- CBN-grinded

- From Ø 6.3 mm to 80mm

- Different versions (60°, 82°, 90° and 120°)

Countersinks for machining of abrasive and hardened steels

- Different quality stages (carbide-tipped and carbide)

- Different shank types (cylindrical and Weldon)

- CBN-grinded

- From Ø 6.3 mm to 45 mm

- Different versions (82° and 90°)

Countersinks for machining of rust and acid-resistant steels

- Different quality stages (ASP powder steel, carbide-tipped and carbide)

- Different shank types (cylindrical, Weldon and 3 surface shank)

- CBN-grinded

- From Ø 6.3 mm to 45 mm

- Different versions (82° and 90°)

Countersinks for machining of graphite, carbon, glass fiber composites

- Specially adjusted coating

- Cylindrical shank

- CBN-grinded

- From Ø 10.4 mm to 31 mm

- 90° version

Countersinks for machining of titanium and titanium alloys

- Different quality stages (ASP powder steel, carbide-tipped and carbide)

- Different shank types (cylindrical, Weldon and 3 surface shank)

- CBN-grinded

- From Ø 6.3 mm to 45 mm

- Different versions (82° and 90°)

Countersinks for machining of hardox 500 and exotic materials

- Specially adjusted coating

- Cylindrical shank

- CBN-grinded

- From Ø 10.4 mm to 31 mm

- 90° version