Subland Drills

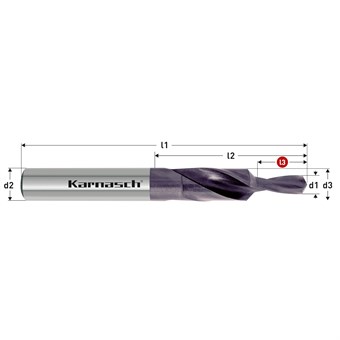

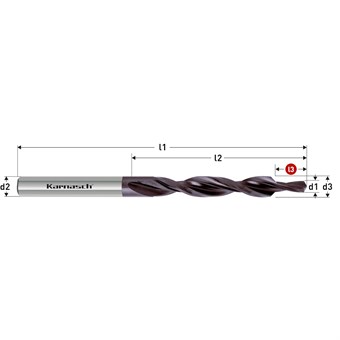

Multi-bevel subland step drills are among the standard products found in the tool industry today, and are often in tough continuous use. That is why Karnasch develop subland step drills using the the latest tool technology and materials. Karnasch multi-bevel subland step drills are available in different versions for every application. The TITAN-TEC tool coating makes the multi-bevel subland step drills from Karnasch additionally unique and increases the tool life in particular.Karnasch premium subland step drills and short stepped drill bits

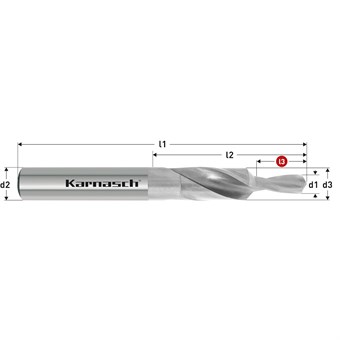

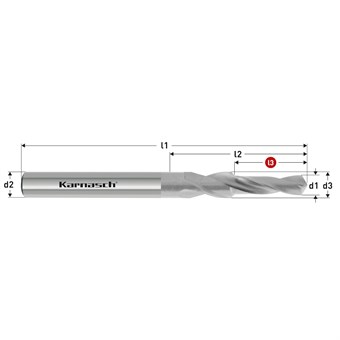

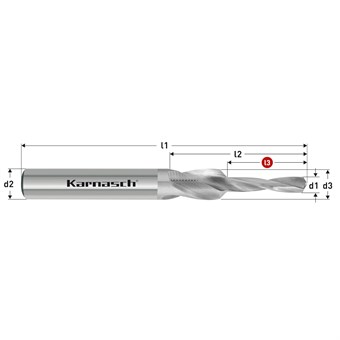

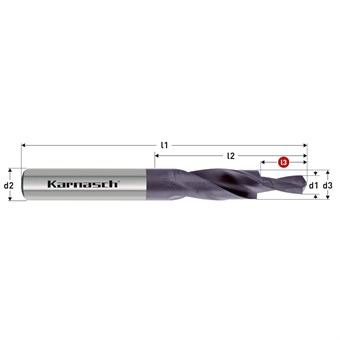

Karnasch HSS-XE and HSS-XE TITAN-TEC 90° subland step drills / short stepped drill bits for countersunk screws, 180° screw head sinking as well as thread core hole and countersinking in one working process, in premium quality for the machining of steel, stainless steel, cast iron, aluminum and plastics. Quality grade fine and medium for through hole and for thread core-hole.

Subland step drills / short stepped drill bits belong to the standard products in the tool industry and are often in continuous use. That is why Karnasch relies on the highest quality and the latest tool technologies. Karnasch subland step drills / short stepped drill bits are available in different designs for any application. The TITAN-TEC tool coating makes the Karnasch subland step drills / short stepped drill bits unique and considerably increases tool life.

Karnasch subland step drills with specially developed cutting geometries

Karnasch Professional Tools subland step drills / short stepped drill bits are available in HSS-XE- and HSS-XE TITAN-TEC versions.

The HSS-XE subland step drills / short stepped drill bits are made of high quality special steel "XE" for significantly longer tool lives as compared to HSS steels. The TITAN-TEC coated subland step drills / short stepped drill bits also considerably increase tool lives, even during dry machining (without or with only minimal cooling).

Due to the wide range of subland step drills / short stepped drill bits, nearly all steels that are difficult to machine, such as stainless and acid-resistant stainless steels, non-ferrous and light metals, cast iron and many more, can be used.

Applications of subland step drills / stepped drill bits

- For screws and through holes 90° according to DIN-ISO 273 and countersinks according to DIN 74 sheet 1, form A, quality grade fine.

- For countersunk screws ISO 2009, 2010, 7046/DIN 963, 964, 965, 966.

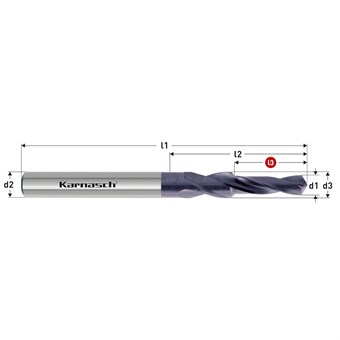

- For screws and through holes 180° according to DIN-ISO 273 and screw head sinking, form H, J, K. Quality grade medium according to DIN 74 sheet 2.

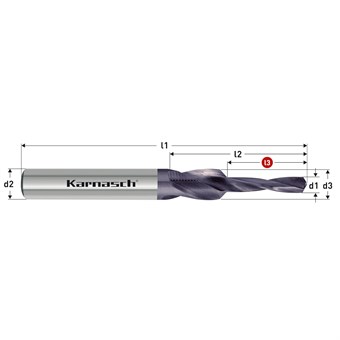

- For thread tapping drill holes 90° according to DIN 336 sheet 1, with countersinks 90° (similar to DIN 69, quality grade medium).

- For screws and through holes 90° according to DIN-ISO 273 and counterbores according to DIN 74, Sheet 1, Form A, quality grade fine.

- For screws according to ISO 2009, 2010, 7046, 7047 (DIN 963, 964, 965, 966).

- For screws and through holes 180° according to DIN-ISO 273 and counterbores according to DIN 74, sheet 2, form H, J, K, quality medium.

- For screws to DIN 912, 6912, 7984, ISO 1207 (DIN 84).

- For screws and through holes 90° according to DIN-ISO 273 and countersinks according to DIN 74 sheet 1, form A, medium version. For screws ISO 2009, 2010, 7046, 7047 ( DIN 963, 964, 966).

Characteristics of subland step drills / stepped drill bits

- HSS-XE & HSS-XE TITAN-TEC

- Diameter ranges from M2 to M12

- Counterbores 90°, 180°

- Especially suitable for drilling with simultaneous sinking into profile materialSpecially developed TITAN-TEC Beschichtung

- Subland step drill 90° DIN 8374, DIN 8378

- Subland step drill 180° DIN 8376

- Especially suitable for NC machines due to high positioning accuracy, best centering properties and high stability

- Very stable and narrow concentricity tolerances between drill and countersink diameters guarantee exact alignments