- Home

- |

- Coatings

- |

- D-CC Diamond Coating

- |

- Diamond Coated Solid Carbide End Mill, Corner Radius

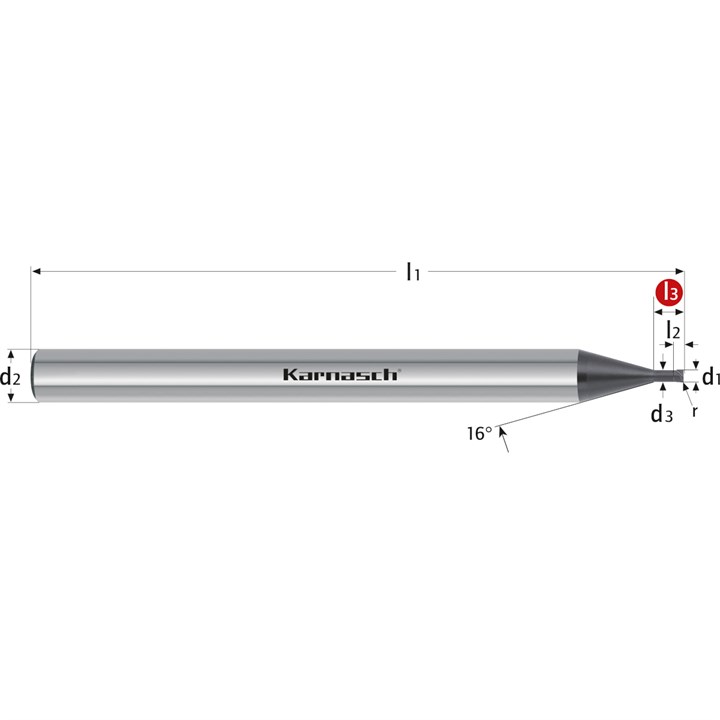

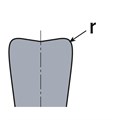

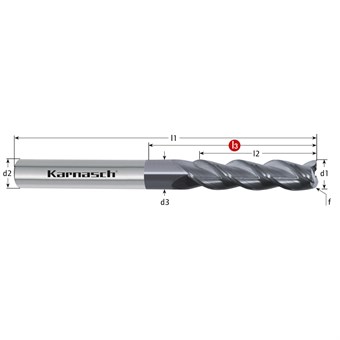

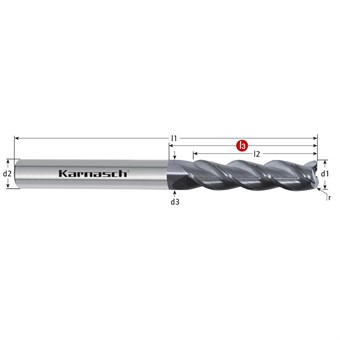

Diamond Coated Solid Carbide End Mill, Corner Radius

Product Description

Diamond coated solid carbide end mill with corner radius.

When carbide is machining carbide

During the machining of difficult materials, such as cemented carbide, tools will reach their limits and will push up production costs – due to

long processing times. We have enhanced the productivity and efficiency by using the latest Karnasch end mills (tools with geometrically defined cutting edges).

Advantages:

- Diamond coated Karnasch carbide end mills reduce manufacturing

costs and machining time - The production of complex 3-D moulds and contours is possible

- You achieve a better surface

- Machining of carbide over 2.000 HV is possible

- Excellent cutting edge stability up to 10.000 HV

- No white erode zones

D-CC Coating

Specially developed for carbide cutting.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 700 degrees C

This optimized droplet-free diamond coating increases the tool life of carbide cutting significantly. Due to the optimal pre-treatment, the special layer structure and the layer thickness, this coating is optimally designed for the machining of hard metal.

Product Downloads

There are no download types with downloads for this product.