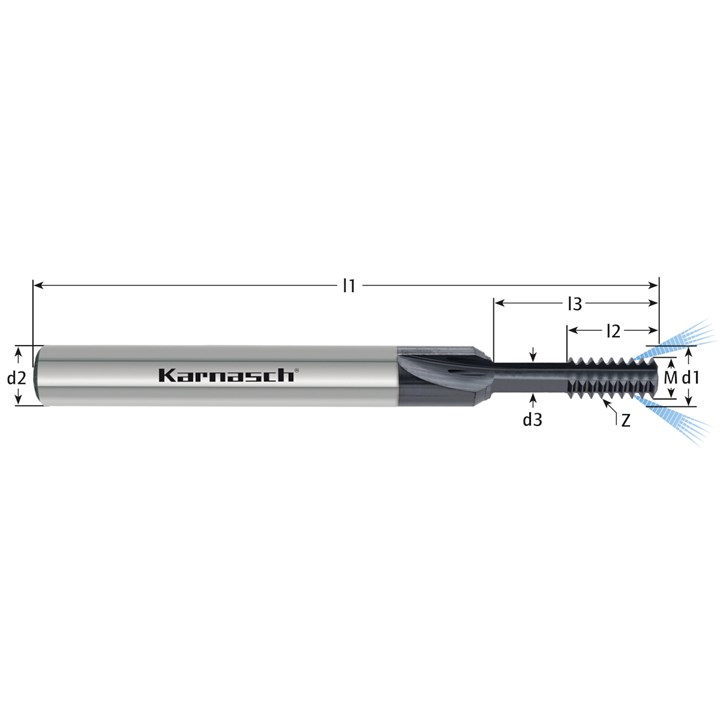

Solid Carbide Thread Mill, Internal Cooling, Logarithmical Relief, Ground

Product Description

Karnasch solid carbide thread mills are arc shaped logarithmically grinded this results in a significant higher tool live. Due to the logarithmic grinding the rake angle and relief remain stable, which leads to increased process reliability.

Due to our special profile shape we ensure, that the thread is free from distortions and stay

dimensionally true.

USAGE:

The major advantages are:

-Suitable for comented carbide up to 80 HRC

-Special coatings for machining different materials

-No burr formation

-Special logarithmic grinding

-Standart dimensions available from stock

NANO SPIN Coating

Specially developed for our whirling thread cutters for steel processing.

- Coating technology: PVD

- Micro hardness: 3200 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900 degrees C

This optimized NANO spin coating was specially developed for our whirling thread cutters. Due to its very good sliding properties and temperature stability, this coating is suitable for machining steels up to 70 HRC.

Product Downloads

There are no download types with downloads for this product.