Spade Drills

Reduce your costs per drilling with Karnasch spade drills and increase the efficiency of your production. Karnasch's range of spade drills is the efficient solution for drilling with exchangeable cutting heads. Karnasch spade drills are highly efficient drilling tools with outstanding performance parameters in terms of tool life and production tolerance.Spade drills by Karnasch with exchangeable solid carbide/powder steel cutting heads

The premium quality spade drills with quick-change function for quick exchanging of the cutting heads. Particularly suitable for CNC machines such as pillar drilling machines or radial drilling machines.

Reduce your costs per drilling with Karnasch spade drills and increase the efficiency of your production. Karnasch's range of spade drills is the efficient solution for drilling with exchangeable cutting heads. Karnasch spade drills are highly efficient drilling tools with outstanding performance parameters in terms of tool life and production tolerance. Spade drills replace the outdated drilling technology of drilling tools consisting entirely of HSS / HSS-Co cobalt / powder steel and represent an excellent addition to the range of solid carbide drills.

Advantages of spade drills with quick-change system

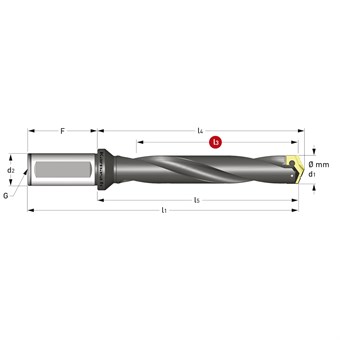

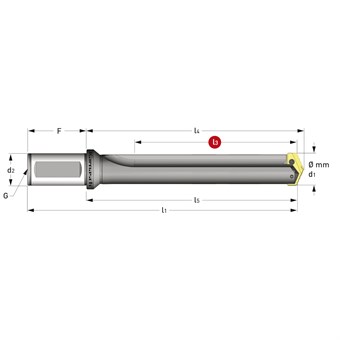

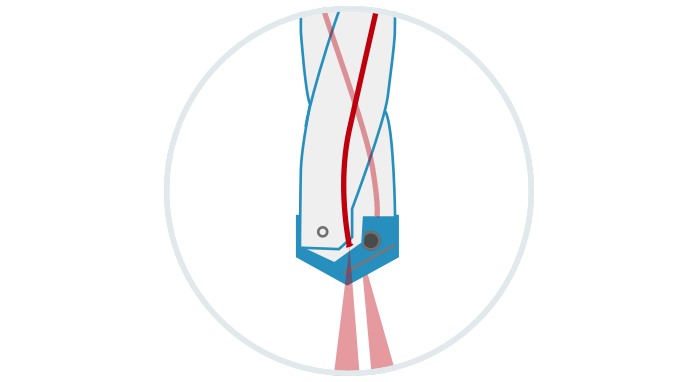

Karnasch spade drills consist of two components, the tool holder and the cutting inserts. The spade drills also have an internal coolant supply, which ensures excellent chip removal, even when drilling deep holes.

Spade drills are particularly suitable for CNC machines such as pillar drilling machines and radial drilling machines as well as all traditional or manual drilling machines. Learn more about the advantages of Karnasch spade drills in the following overview.

- Only 14 holders are required to cover the diameter range Ø 9.5 - 114 mm.

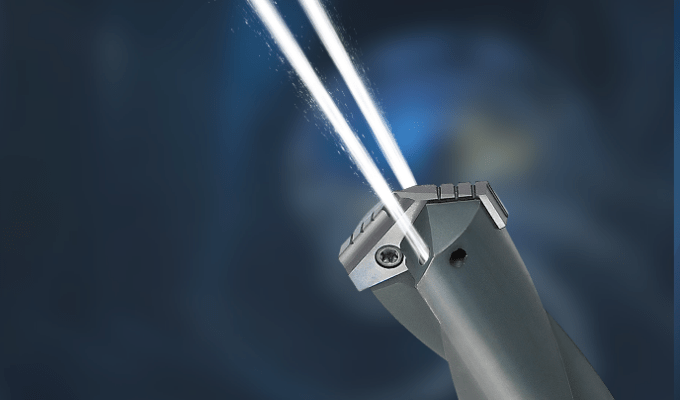

- Internal coolant supply for excellent chip removal even when deep drilling.

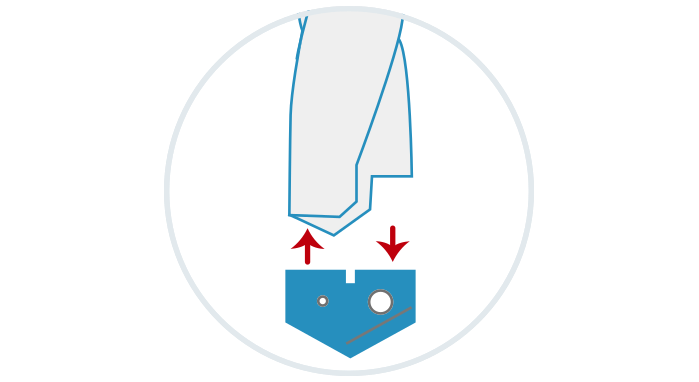

- The high-precision connection between holder and cutting insert guarantees narrowest tolerances and cutting inserts that are easy to change.

- The cutting inserts are made of powder steel or carbide. All cutting inserts also have coatings that are optimized for their intended uses. This combination results in a significantly higher cutting performance and tool life.

- Due to the quick exchange of the cutting inserts, the spade drill is immediately ready for use again. It is not necessary, as in the case of conventional steel drills, to recondition or sharpen the complete drill.

- The optimized XR cross-sectional cutting edge grinding on the cutting inserts reduces the cutting forces significantly and improves the stability of the entire cutting insert.

- The chip breaker results in better chip removal and a lower cutting force.

Drills with internal cooling for optimal cooling and lubrication

Maximum resilience for challenging applications.

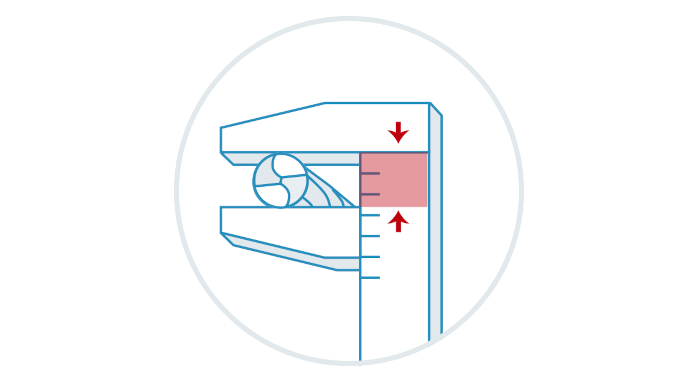

Karnasch tool cooling guarantees optimal cooling results and presents obvious advantages as compared to external cooling. On the one hand, the cooling of the cutting edge can individually be optimized, with the result that the heat development is considerably reduced. The special power chamber by Karnasch ensures an increased coolant leak - at the same pressure but also at low pressure. On the other hand, Karnasch tool cooling removes the chips more efficiently and improves the overall cutting performance significantly. In addition to higher productivity, Karnasch tool cooling enhances tool lives and prevents premature tool breaking, which in turn leads to considerable cost savings.Advantages of the Karnasch cooling channel drills:

- Optimal tool life even under highest loads (optimal cooling and lubricating effect)

- Increased drilling speed

- Chips are more easily removed from the drilling range

Cutting Inserts

Longer Tool Lives

Diameter Range

Product Characteristics

Spade drills are the ideal drilling tools for all modern CNC machines such as:

- Numerically controlled pillar drilling machines / radial drilling machines

- Numerically controlled lathes

- Machining centers

- Carbide inserts are preferably used here

Spade drills are the ideal drilling tools for all traditional / manual drilling machines such as:

- Pillar drilling machines

- Radial drilling machines

- All types of vertical drilling machines

- Non-numerically controlled lathes

- Powder steel inserts are preferably used here

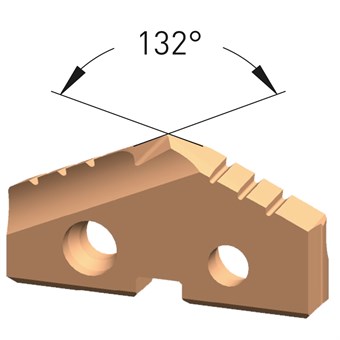

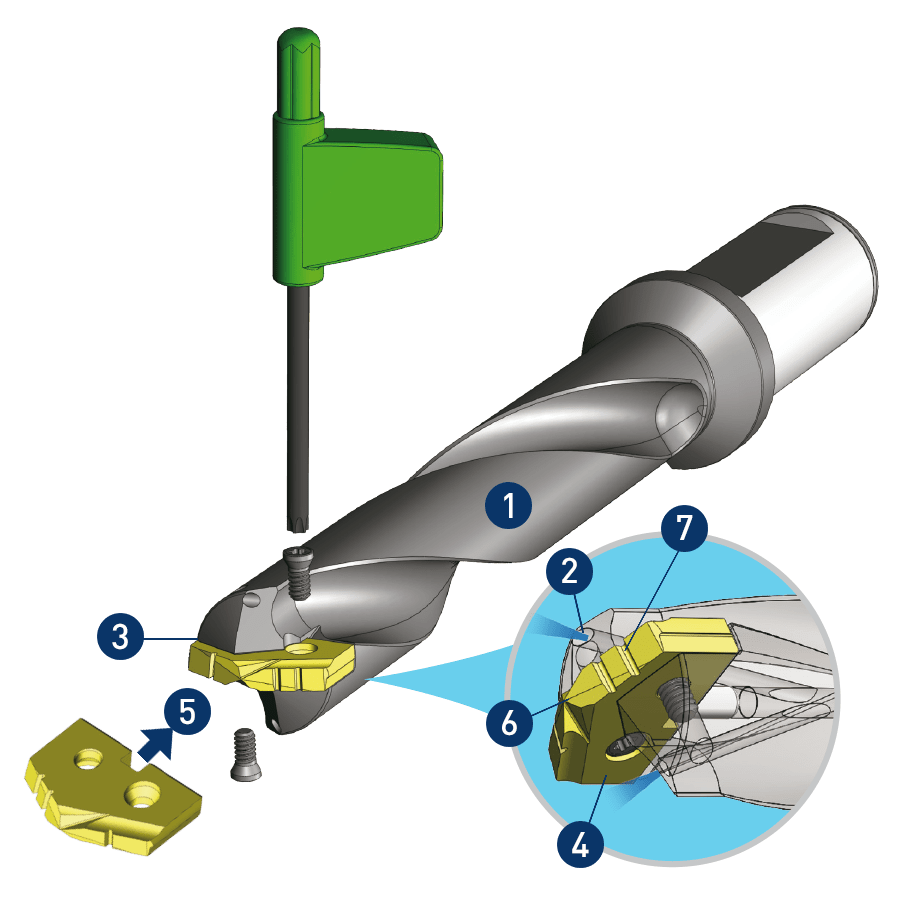

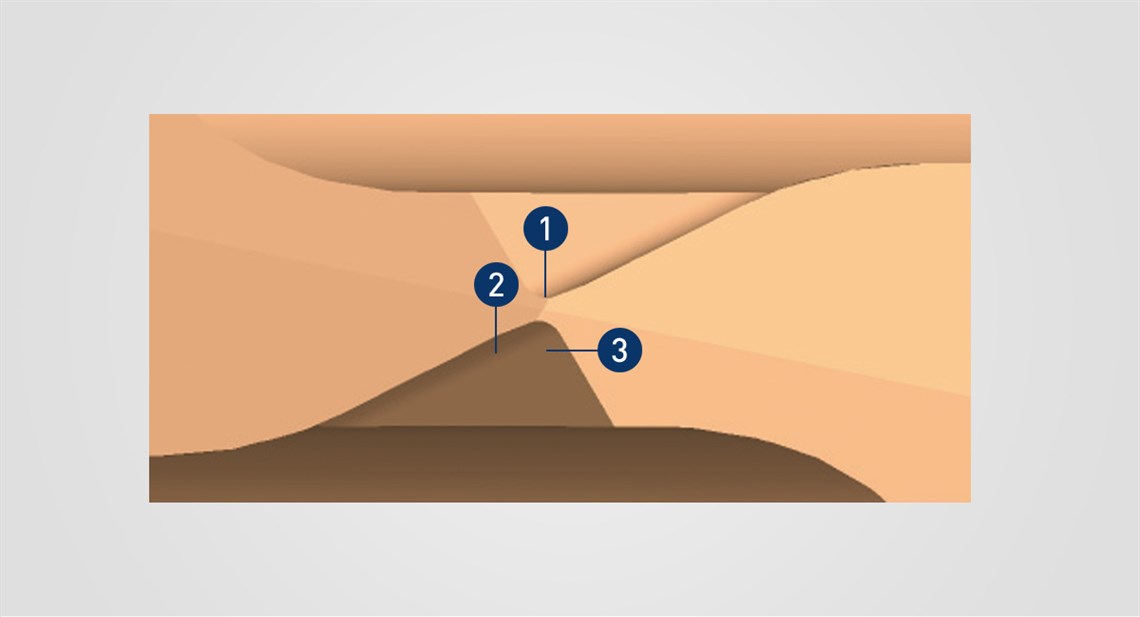

1. Drill tip

- The axial forces are reduced by up to 20% as compared to conventional drills due to tapered center cutting edges

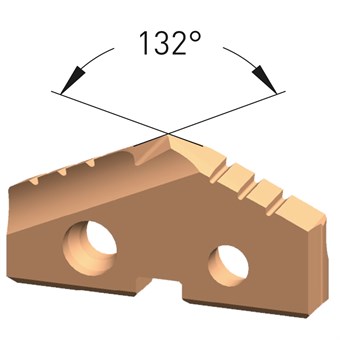

2. XR cross-sectional cutting edge grinding

- Improves the stability of the cutting edges

- Improves the stability of the entire cutting insert

3. Two back flank surfaces

- Reduces friction with the workpiece

- Improves self-centering

- Reduces axial forces

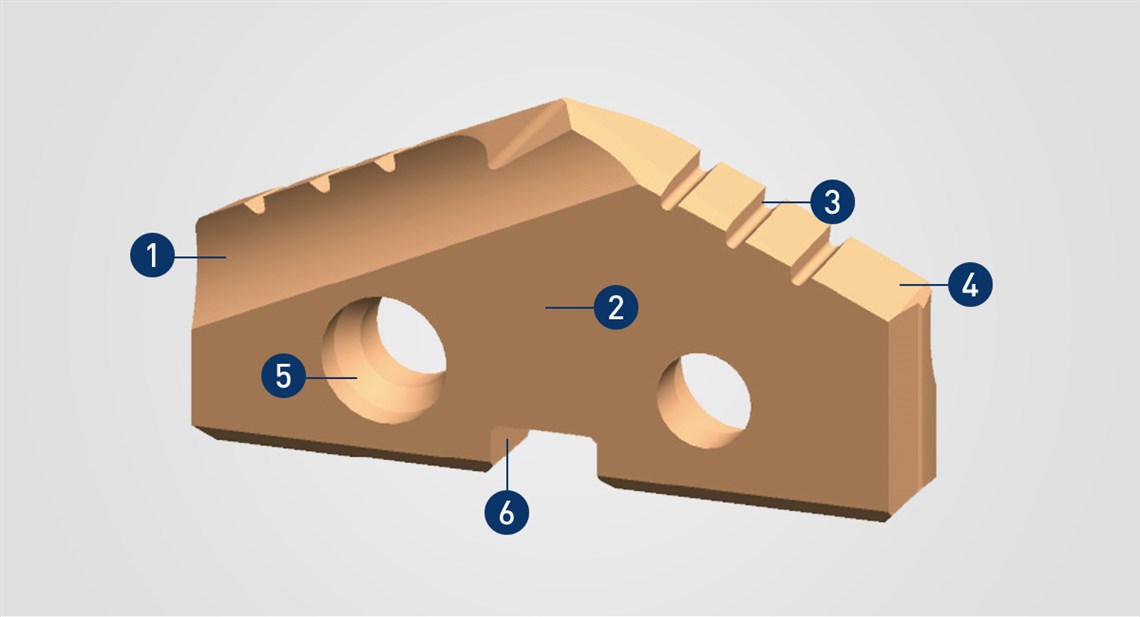

1. Chip breaker

- Chip breakers improve chip removal and reduce cutting forces

2. Coating

- All inserts are given special tool coatings

3. Chip breaker grooves

- Reduces the chip length

- This improves chip removal and reduces cutting forces

4. Diameter chamfer

- Improves the stability of the cutting insert

- Reduces wear of the external diameter of the cutting insert

- Improves the tool's surface

5. Fixing holes

- Safe and reliable attachment of the cutting inserts for maximum stability during the drilling process

6. Positioning slot

- Guarantees accurate positioning of the cutting inserts during radial rotation