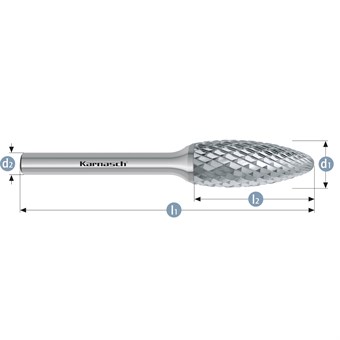

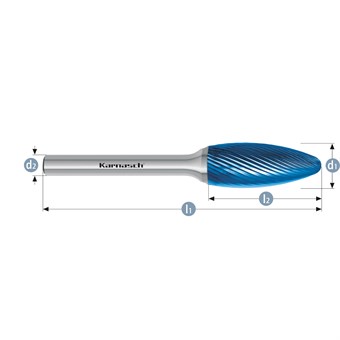

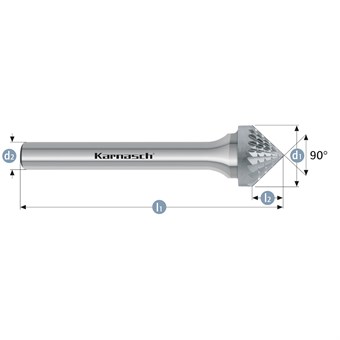

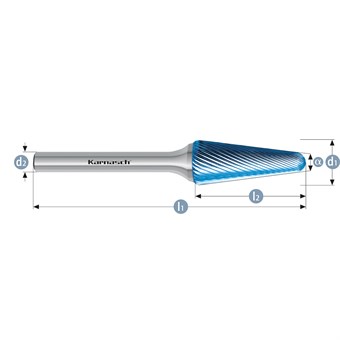

Rotary Burrs

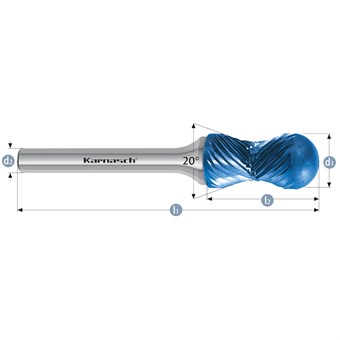

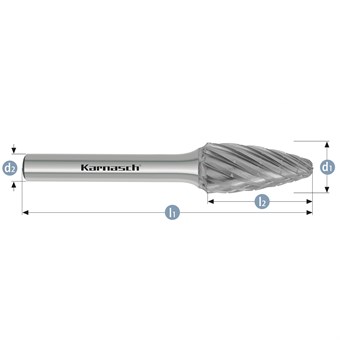

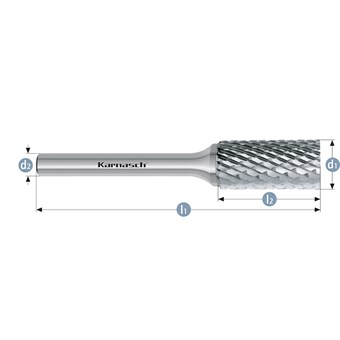

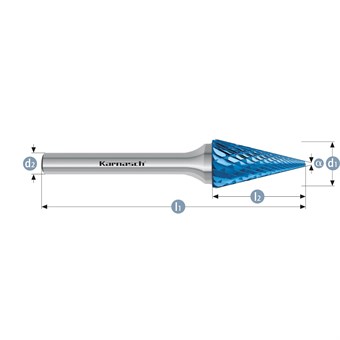

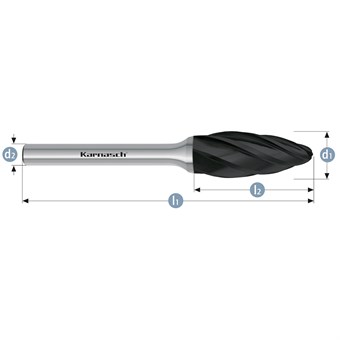

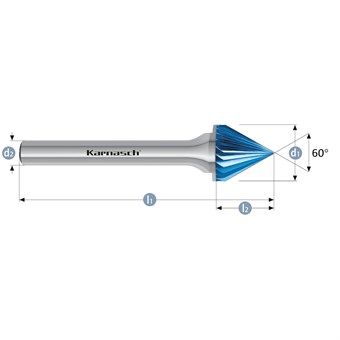

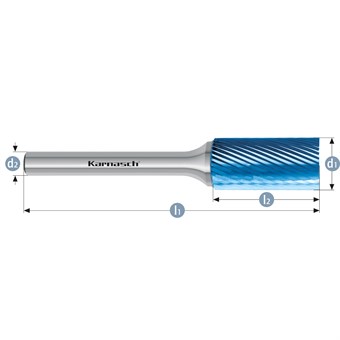

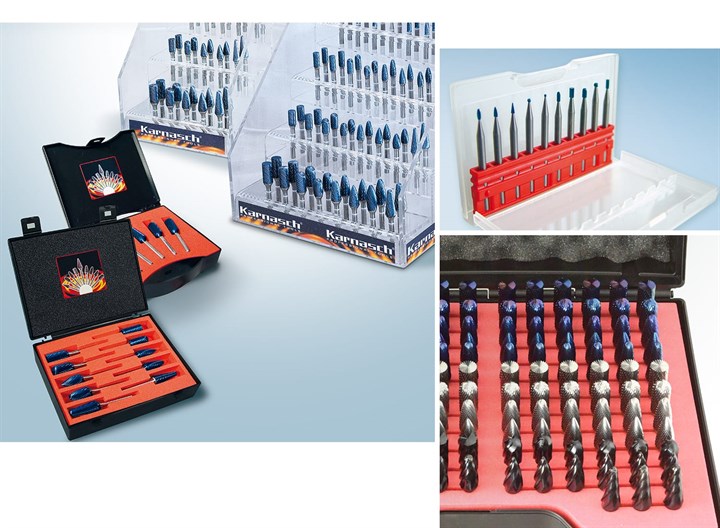

With 15 different cutting edge shapes and 9 different cutting edge geometries, as well as special end mills (e.g. locksmith tools) and micro cutters (microtools), the Karnasch burrs and rotary burrs cover every possible area of application. They are available in the tool coating variants BLUE-TEC and BLACK-TEC.The world's most comprehensive stock range of carbide burrs / carbide rotary burrs

Karnasch Professional Tools offers more than 1,800 different burrs / rotary burrs in stock.

With 15 different cutting edge shapes and 9 different cutting edge geometries, as well as special end mills (e.g. locksmith tools) and micro cutters (microtools), the Karnasch burrs and rotary burrs cover every possible area of application. They are available in the tool coating variants BLUE-TEC and BLACK-TEC.

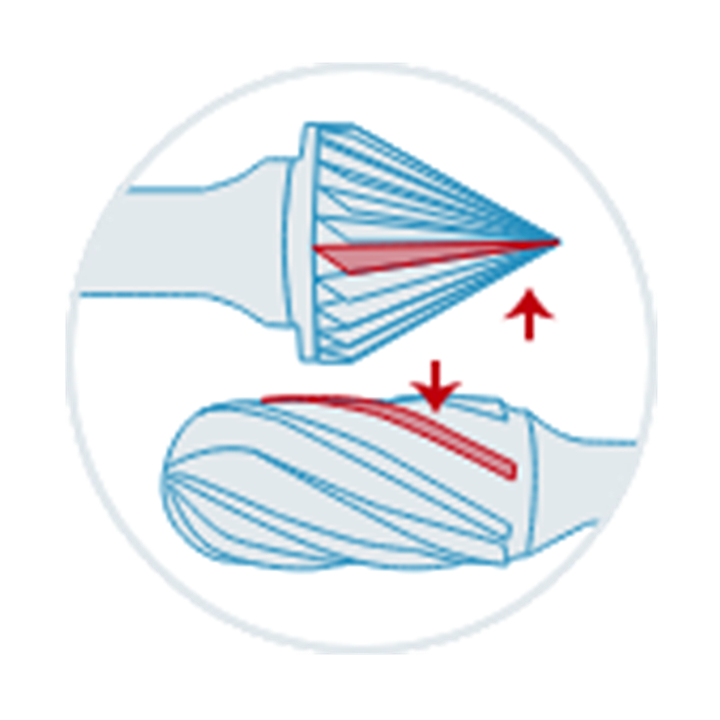

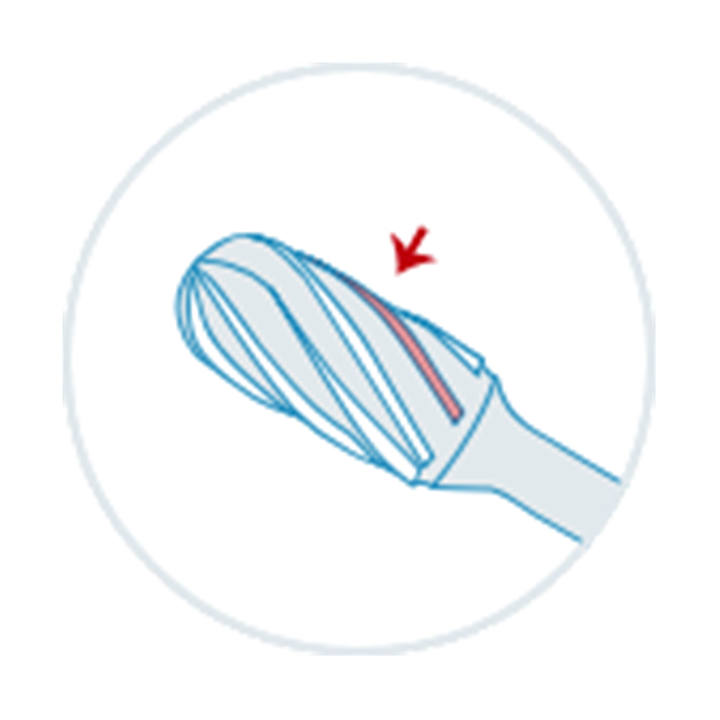

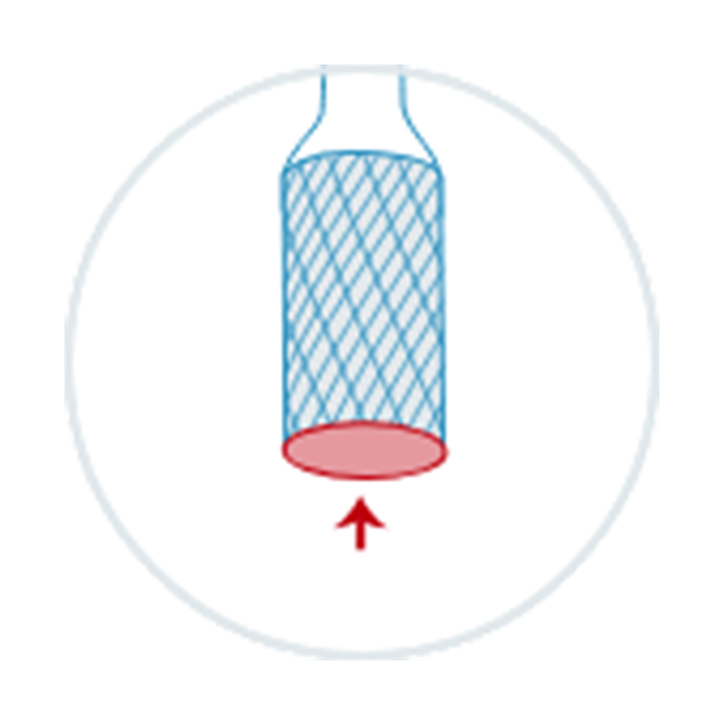

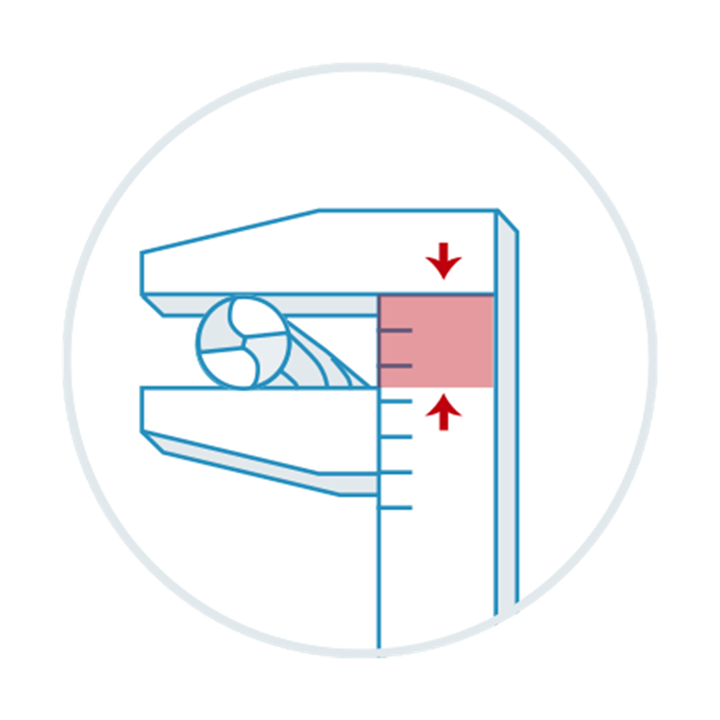

Karnasch carbide burrs and carbide rotary burrs have optimized front sides for an improved cutting efficiency and extremely smoothly grinded milling surfaces (mirror grinding) for higher material removal. Only the best micro-grain carbide types are used for Karnasch burrs / rotary burrs and every single burr is 100% tested for robustness and safety.

Karnasch carbide burrs and carbide rotary burrs enable the machining of steel, stainless steel, aluminum, non-ferrous metal, soft metal, plastic, GRP/CRP, nickel, cobalt and titanium alloys and also serve as locksmith tools / firefighter tools.