- Home

- |

- Products

- |

- Drilling

- |

- Spade Drills

- |

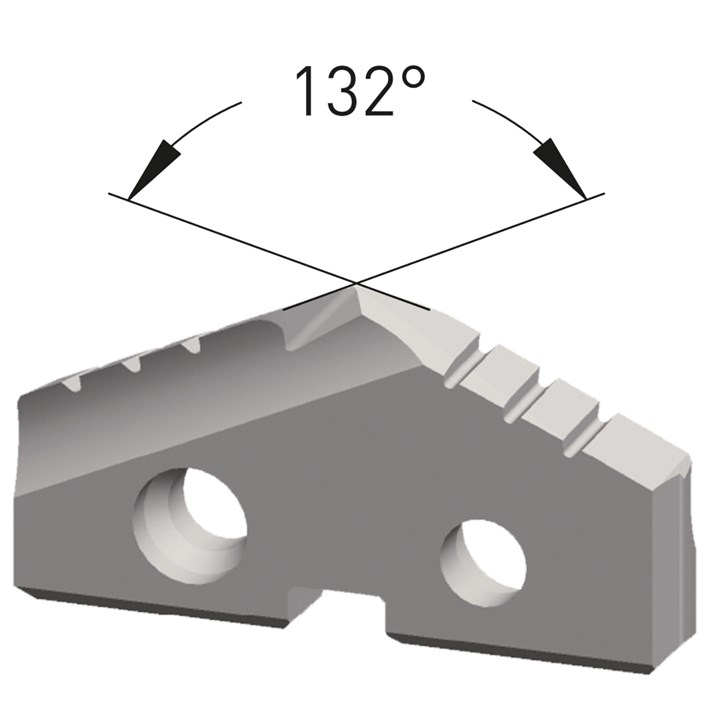

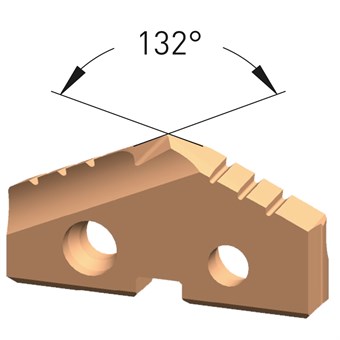

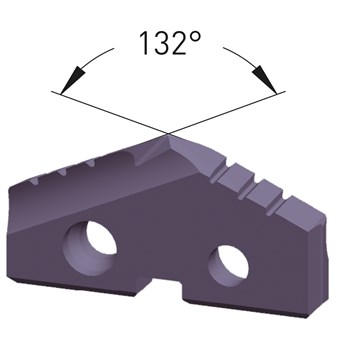

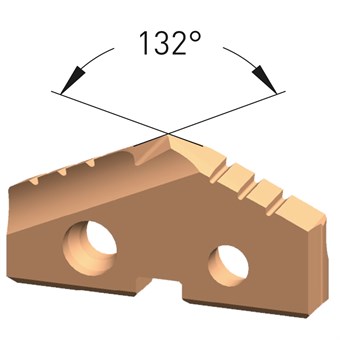

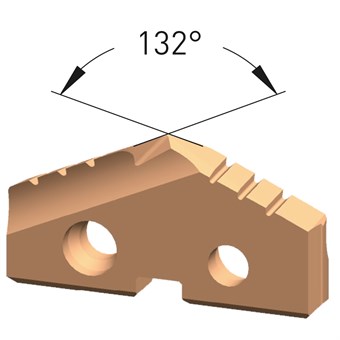

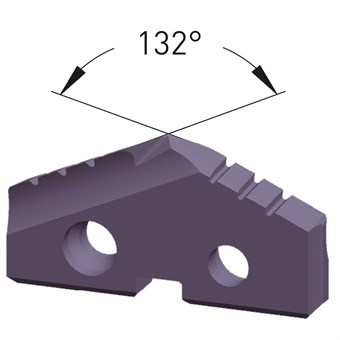

- 132 Degree Carbide 20/30 Spade Drill Insert for Fiberglass, Carbon fiber, Graphite

132 Degree Carbide 20/30 Spade Drill Insert for Fiberglass, Carbon fiber, Graphite

225510_P

More details on catalogue page number 310 - Click to view

From €36.80 Excl VAT

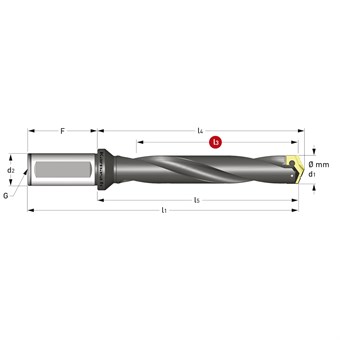

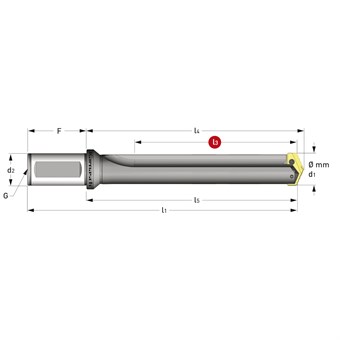

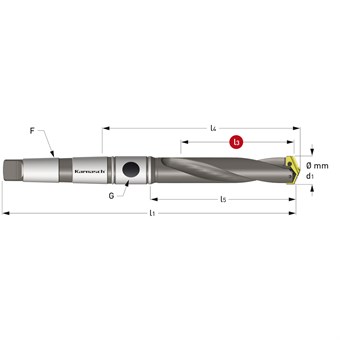

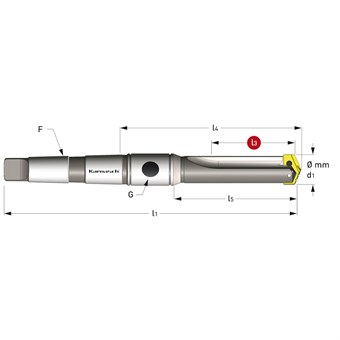

Reduce your drilling cost by using karnasch spade drill spade drill is one of the main interchangeable insert drill from karnasch. It is a highly efficient drilling tool with superior performance, designed to substitute those traditional hole drilling products.

Product Description

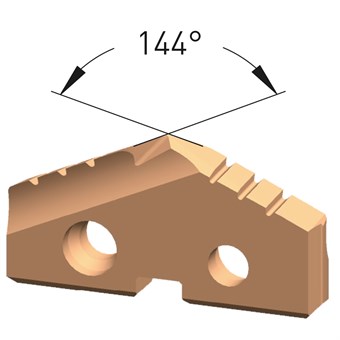

Specially coated for drilling in abrasive materials such as: glass fiber, carbon fiber [GFK, CFK], graphite and similar.

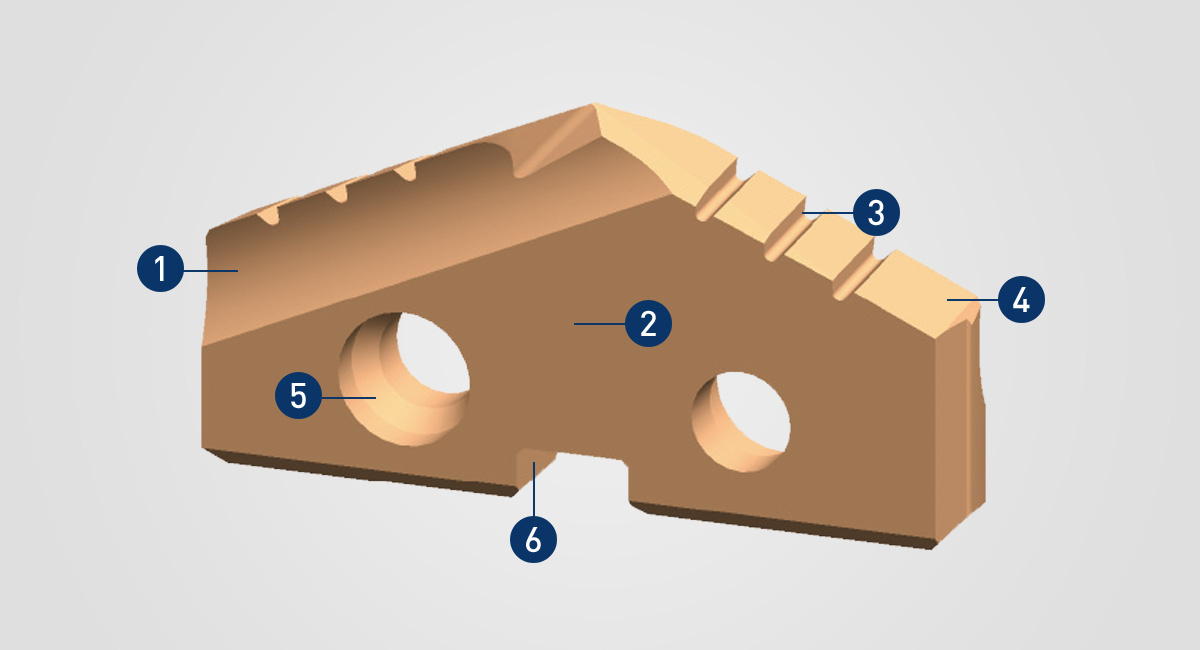

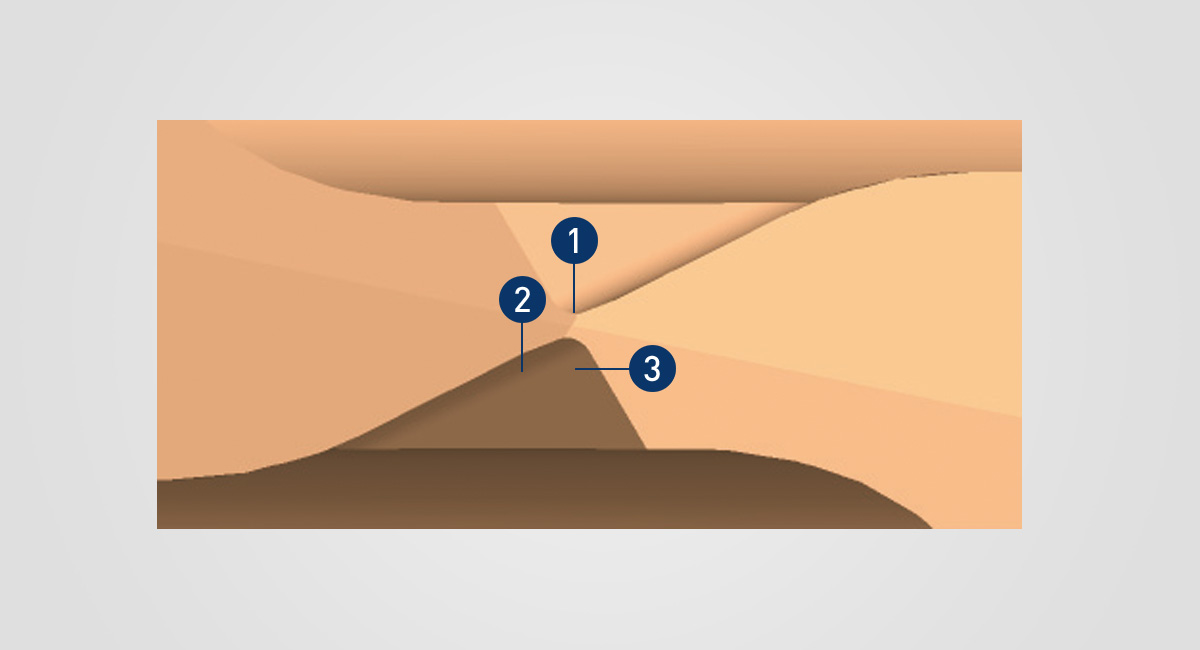

Description of insert diagram:

|

| |

|  |

Product Downloads

There are no download types with downloads for this product.