- Home

- |

- Premium Tool Coatings

Karnasch tool coatings

Tool coatings for longer tool lives

For optimal machining results, professionals rely on tool coatings. Tool coatings have the advantage that they increase tool life significantly - even with insufficient cooling or lubrication. In addition, tool coatings achieve a consistent increase in productivity in machining processes.

Karnasch Professional Tools develops high performance tool coatings that are specially adjusted to the materials to be machined. Karnasch tool coatings convince with their excellent characteristics, not only in tool life and accuracy, but also in the worldwide unique tool tolerance, especially for diamond-coated tools for graphite processing.

Karnasch offers several tool coatings for the machining of various materials: from droplet-free nanocrystalline diamond toll coatings frpm BLACK-TEC, BLUE-TEC, BLUE-DUR and DURABLUE to HXC-Nano3, Tcx3, NHC-7000, Kx, DMC-X2, TiN as well as TiN-GOLD.

Karnasch tool coatings in highest quality

Professionals rely on tool coatings! Achieve optimal results with the premium coatings by Karnasch. Each of our coatings is adjusted to the materials that are to be processed.

Choose between ten special coatings: from droplet-free nanocrystalline diamond coating over BLACK-TEC, BLUE-TEC, BLUE-DUR and DURABLUE up to HXC-Nano3, Tcx3, NHC-7000, Kx, DMC-X2, TiN and TiN-GOLD.

Keeping cool even under extreme conditions

Karnasch high precision tools are available with heat-resistant high performance coatings for longer tool lives.

The various coatings are adjusted to the materials that are to be processed.

Hard and high-speed machining. Ideal for dry machining.

- Coating technology: PVD Multilayer

- Micro hardness: 3400 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized and special Karnasch Blue-Tec coating simplifies the processing and handling of materials that are difficult to machine. Specially developed for dry work, it also increases process reliability under the most difficult working conditions. With Karnasch Blue-Tec coated tools, you achieve unique tool lives and performance in all steel grades.

Shop Now

Soft and high-speed machining. Ideal for dry machining of aluminum.

- Coating technology: PACVD Plasma Assisted Chemical Vapour Deposition

- Micro hardness: 5000 HV0.05

- Coating material: DLC Diamond-Like-Carbon

- Coating thickness: Diameter-related

- Max. operating temperature: 500°C

This optimized and special Karnasch Black-Tec coating simplifies the processing and handling of non-ferrous metals and plastics. Specially developed for dry work, it also increases process reliability under the most difficult working conditions. With Karnasch Black-Tec coated tools, you achieve excellent friction and sliding qualities and reduce the formation of build up edges.

Shop Now

Best machining results in all steel grades for wet and dry machining.

- Coating technology: PVD Multilayer

- Micro hardness: 3400 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized and special Karnasch Blue-Dur coating simplifies the processing and handling of materials that are difficult to machine. Specially developed for dry work, it also increases process reliability under the most difficult working conditions. With Karnasch Blue-Dur coated tools, you achieve unique tool lives and performance in all steel grades.

Shop Now

Best machining results in all steel grades for wet and dry machining.

- Coating technology: PVD Mulitlayer

- Micro hardness: 3400 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized and special Karnasch Durablue coating simplifies the processing of materials that are difficult to machine. The increased surface hardness and heat resistance strongly increase process reliability under difficult working conditions.

Shop Now

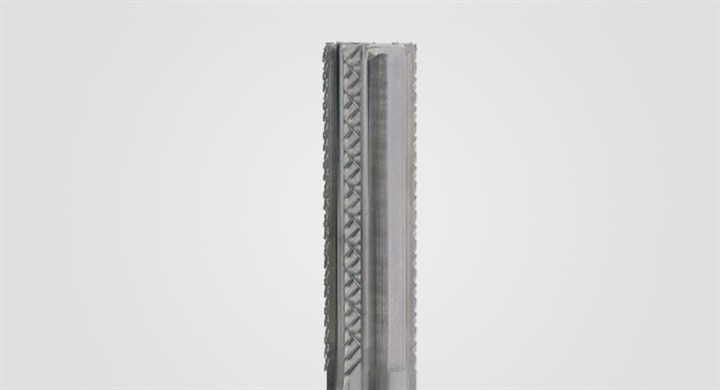

Diamond coating for maximum tool life when drilling and milling.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 700°C

This optimized droplet-free diamond coating increases the tool life of GRP/CRP and graphite machining significantly. As a result of the true contour diamond coating and the 100% control of all drills and cutters, a unique tool life and performance is achieved even with the smallest dimensions.

Shop Now

For the machining of GRP/CRP/composites and graphite.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

Max. operating temperature: 650°C

This optimized droplet-free diamond coating increases the tool life of GRP/CRP and graphite machining significantly. As a result of the true contour diamond coating and the 100% control of all drills and cutters, a unique tool life and performance is achieved even with the smallest dimensions.

Shop Now

For the machining of GRP/CRP/composites and graphite.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 650°C

This optimized droplet-free diamond coating increases the tool life of GRP/CRP and graphite machining significantly. As a result of the true contour diamond coating and the 100% control of all drills and cutters, a unique tool life and performance is achieved even with the smallest dimensions.

Shop Now

For the machining of GRP/CRP/composites and graphite.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 650°C

This optimized droplet-free diamond coating increases the tool life of GRP/CRP and graphite machining significantly. As a result of the true contour diamond coating and the 100% control of all drills and cutters, a unique tool life and performance is achieved even with the smallest dimensions.

Shop Now

For the machining of hardened steels up to 70 HRC / stainless steels and titanium.

- Coating technology: Sputtering

- Micro hardness: 3800 HV0.05

- Coating material: TiAlN/TiSiN based

- Coating thickness: Diameter-related

- Max. operating temperature: 1100°C

The silicon doping gives HXC-Nano³ a particularly high hardness and oxidation resistance. The special coating process achieves very smooth surfaces and improved coating adhesion, which are ideal for the machining of hardened steels, stainless steels or titanium.

Shop Now

For the machining of hardened steels.

- Coating technology: PVD monolayer

- Micro hardness: 3400 HV0.05

- Coating material: AlTin/ZrN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized Karnasch TCX3 coating simplifies the processing of stainless materials and the machining of nickel and cobalt alloys. Due to their special microstructure and smooth surface, the chips are optimally removed. This leads to a reliable machining process and an outstanding tool life.

Shop Now

Best machining results in all non-ferrous metals, plastics and CFRP/GFRP.

- Coating technology: PACVD Plasma Assisted Chemical Vapour Deposition

- Micro hardness: 7000 HV0.05

- Coating material: DLC

- Coating thickness: <0.7µ

- Max. operating temperature: 900°C

This outstanding NHC-7000 coating simplifies the processing of non-ferrous metals, plastics and GRP/CRP. The very thin, very smooth and extremely hard coating enables exceptional tool life and surfaces, even with aluminum >6% Si.

Shop Now

For sawing steel and stainless steel.

- Coating technology: PCD Multilayer

- Micro hardness: 3600 HV0.05

- Coating material: TiAlN

- Coating thickness: ca. 3µ

- Max. operating temperature: 800°C

This optimized Karnasch KX coating for circular saw blades enables higher cutting speeds and a much longer tool life compared to steam-treated circular saw blades. The coating makes the circular saw blades ideal for the use with minimum lubrication/spray lubrication as well as for automatic machines.

Shop Now

For milling of steel up to 55 HRC.

- Coating technology: Sputtering

- Micro hardness: 3700 HV0.05

- Coating material: AlTin

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

The WRC² coating was specially developed for the machining of materials up to 55 HRC. The increased aluminum content contributes to better temperature stability and makes WRC² the first choice for the machining of steels and castings up to 55HRC in both wet and dry machining.

Shop Now

For drilling in steel up to 52 HRC.

- Coating technology: Sputtering

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

This DVC-X2 coating is universally suitable for the machining of most steels. An additional smoothing of the already droplet-free coating can be achieved by an optional finishing.

Shop Now

For drilling in steel up to 52 HRC.

- Coating technology: Sputtering

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

This universally applicable DVC-X2² Nano-Finish coating is very well suited for drilling up to 55 HRC. Due to the additional finishing of the already droplet-free coating, an optimal chip transport is guaranteed.

Shop Now

For steels up to <1400 N/mm².

- Coating technology: PVD

- Micro hardness: 2700 HV0.05

- Coating material: TIN

- Coating thickness: Diameter-related

- Max. operating temperature: 600°C

This optimized TiN coating for our taps convinces by its high hardness and is universally applicable. Due to the low coefficient of friction, the tool life is noticeably increased even during dry machining (without/with little cooling).

Shop Now

For considerably longer tool life in all types of steel for wet and dry machining.

- Coating technology: PVD

- Micro hardness: 2700 HV0.05

- Coating material: TiN

- Coating thickness: Diameter-related

- Max. operating temperature: 600°C

This optimized TiN gold coating provides for a substantial increase of tool life. Due to its high hardness and low coefficient of friction, significant tool life increases are achieved even with dry machining (without/with little cooling).

Shop Now

Ideal for all steels.

- Coating technology: PVD

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN based

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

Our special Hardcoat coating achieves excellent results when tapping due to its high hardness and yet elastic layer structure.

Shop Now

For universal machining of steel.

- Coating technology: PVD

- Micro hardness: 3300 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized UFX-1 Nano coating was developed especially for universal applications. Due to its very good sliding properties and its thermal resistance, a very high production reliability is achieved.

Shop Now

For the machining of soft to medium-hard steels as well as stainless steels.

- Coating technology: PVD

- Micro hardness: 3300 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized UFX-2 Nano coating was developed especially for universal applications. Due to its very good sliding properties and its thermal resistance, a very high production reliability is achieved.

Shop Now

For steels from soft to medium hard.

- Coating technology: Sputtering

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

This optimized UFX-3 coating is very well suited for universal machining of most steels due to its smooth and droplet-free coating.

Shop Now

For steels from soft to medium hard.

- Coating technology: Sputtering

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

This universally applicable XFN-2 Nano coating is very well suited for universal use in drilling. By an optional finishing of the already droplet-free coating, an optimal chip transport is guaranteed.

Shop Now

For soft, tempered and high-strength steels up to 54 HRC as well as for rust- and acid-resistant steels that are difficult to

- machine.

- Coating technology: PVD

- Micro hardness: 3400 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

Max. operating temperature: 900°C

This optimized TI-X² coating was specially developed for difficult-to-machine materials such as titanium and titanium alloys.

Shop Now

For solid carbide tools for the machining of medium-hard materials such as steel, INOX VA, Inconel and titanium.

- Coating technology: PVD

- Micro hardness: 3400 HV0.05

- Coating material: AlTiSiN

- Coating thickness: Diameter-related

- Max. operating temperature: 1100°C

This optimized INOX HP coating was specially developed for the machining of stainless steels. Due to its special microstructure, material composition on the cutting edges is significantly reduced. In addition, the temperatures are transferred to the chip during machining. This results in considerably longer tool life.

Shop Now

Specially developed for our whirling thread cutters for steel processing.

- Coating technology: PVD

- Micro hardness: 3200 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized NANO spin coating was specially developed for our whirling thread cutters. Due to its very good sliding properties and temperature stability, this coating is suitable for machining steels up to 70 HRC.

Shop Now

Universal for wet, dry and hard machining with high thermal stress.

- Coating technology: PVD

- Micro hardness: 3200 HV0.05

- Coating material: AlTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This optimized UFX-24 coating is particularly suitable for the machining of hardened materials. The temperatures generated during machining are transferred to the chip. This results in longer tool life and higher cutting parameters. Dry machining is also no problem for this coating.

Shop Now

For the machining of stainless materials.

- Coating technology: PVD

- Micro hardness: 3400 HV0.05

- Coating material: AlCrTiN

- Coating thickness: Diameter-related

- Max. operating temperature: 1100°C

This optimized INOX F² coating was specially developed for the processing of stainless steels. Due to its special microstructure, the material composition on the cutting edges is significantly reduced. In addition, the temperatures are transferred to the chip during machining. This results in significantly longer tool life.

Shop Now

Universal for wet/dry machining of all general steels.

- Coating technology: PVD

- Micro hardness: 3200 HV0.5

- Coating material: TiCN

- Coating thickness: Diameter-related

- Max. operating temperature: 400°C

This optimized DVC-X3 coating is ideal for milling unhardened steels due to its hardness and at the same time good toughness. In addition, this coating is particularly wear-resistant and effectively protects the tool from cold welding due to its low coefficient of friction.

Shop Now

For milling steel up to 55 HRC.

- Coating technology: PVD

- Micro hardness: 3500 HV0.05

- Coating material: TiSiN

- Coating thickness: Diameter-related

- Max. operating temperature: 1100°C

Due to its high hardness and at the same time good toughness, the XVC² coating is very well suited for the machining of steels up to 55 HRC.

Shop Now

Specially developed for carbide cutting.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 700°C

This optimized droplet-free diamond coating increases the tool life of carbide cutting significantly. Due to the optimal pre-treatment, the special layer structure and the layer thickness, this coating is optimally designed for the machining of hard metal.

Shop Now

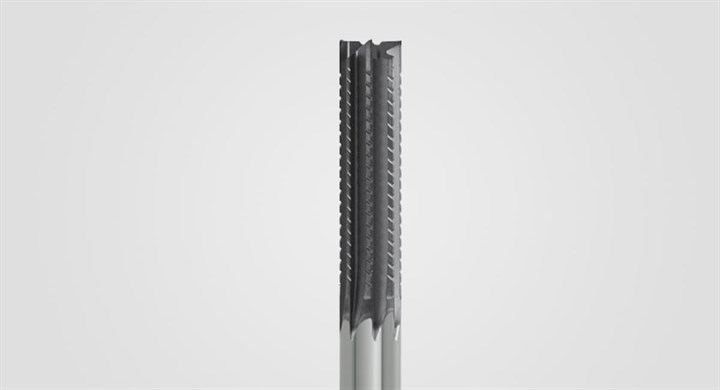

Specially developed for our whirling thread cutters for the machining of CFRP/GFRP and graphite.

- Coating technology: CVD Chemical Vapour Deposition

- Micro hardness: 10000 HV0.05

- Coating material: Diamond

- Coating thickness: Diameter-related

- Max. operating temperature: 700°C

This optimized droplet-free diamond coating increases the tool life during thread whirling of CFRP/GFRP and graphite significantly. Due to the true contour diamond coating and the 100% control of all tools, a unique tool life and performance is achieved even with the smallest dimensions.

Shop Now

For drilling steel <55 HRC.

- Coating technology: PVD

- Micro hardness: 3300 HV0.05

- Coating material: TiAlN

- Coating thickness: Diameter-related

- Max. operating temperature: 900°C

This universally applicable DMC-X2 coating is very well suited for universal use in drilling. The droplet-free coating ensures optimal chip transport, resulting in high process reliability.

Shop Now

Especially for HSS-XE drills.

- Coating technology: PVD

- Micro hardness: 3500 HV0.05

- Coating material: TiAlN based

- Coating thickness: Diameter-related

- Max. operating temperature: 1000°C

This optimized Karnasch TITAN-TEC coating simplifies the processing and handling of materials that are difficult to machine. Especially for dry work, it increases process reliability under the most difficult working conditions. With Karnasch TITAN-TEC coated HSS-XE tools you achieve unique tool life and performance in all steel sorts.

Shop Now