- Home

- |

- Products

- |

- Drilling

- |

- CNC Drills

- |

- Internal Cooling

Internal Cooling

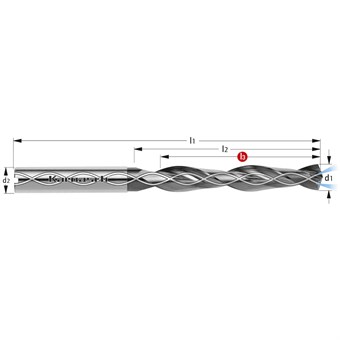

Karnasch tool cooling guarantees optimal cooling results and presents obvious advantages as compared to external cooling. On the one hand, the cooling of the cutting edge can individually be optimized, with the result that the heat development is considerably reduced. The special power chamber by Karnasch ensures an increased coolant leak - at the same pressure but also at low pressure.Maximum resilience for challenging applications.

The Karnasch internal tool cooling guarantees efficient chip removal and improves the cutting performance significantly. The heat development within this machining process is considerably reduced by the internal tool cooling. The special twist cooling and the power chamber shank by Karnasch ensure an increased coolant leak - at the same pressure but also at low pressure. In addition to higher productivity, Karnasch internal tool cooling enhances tool lives and prevents premature tool breaking, which in turn leads to considerable cost savings.The Karnasch internal tool cooling is available for solid carbide high performance drills, twist drills, spade drills, powder steel annular cutters, solid carbide rough cutters, solid carbide 3D radius end mills, ball nose end mills as well as morse taper holders.

Sale Article

3059551000

Solid carbide ball nose end mill, with interior cooling, extra long.

€33.00 Excl VAT

306534_P

Pcd- corner radius end mill, positiv, with interior cooling. Pcd = polycriytalline diamond.

From €222.60 Excl VAT

220409_P

Solid carbide high performance twist drill.

From €28.80 Excl VAT

220410_P

Solid carbide high performance twist drill with interior cooling for inconel.

From €73.80 Excl VAT

220412_P

Solid carbide high performance twist drill with interior cooling for titanium.

From €73.80 Excl VAT

220415_P

Diamond coated solid carbide high performance twist drill with internal cooling. Replacement articles, 290120, 290121, 290122.

From €51.60 Excl VAT

220424_P

Iq-drill four-chamfer, 5xd and 8xd with/without interior cooling supply. We optimize your production. this new development from karnasch meets hightest demands on drill quality. Reming after drilling is often not necessary any more. 4 chamfer are optimal adjusted on the drill-diameter and devel.

From €158.55 Excl VAT

220473_P

High capacity solid carbide subland twist drill, with interior cooling.

From €87.35 Excl VAT

220525_P

Solid carbide twist drill/cordrill, 3 cutting edges with interior cooling.

From €48.60 Excl VAT

220526_P

Solid carbide four-chamfer drill with pcd tips.

From €321.31 Excl VAT

220530_P

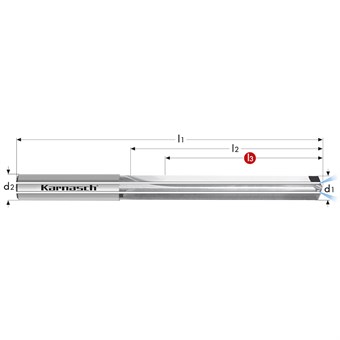

Solid carbide shallow drill 180 degrees for aluminium.

From €104.80 Excl VAT

220806_P

Solid carbide twist drill with interior cooling.

From €20.25 Excl VAT

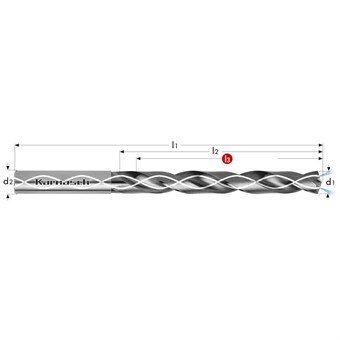

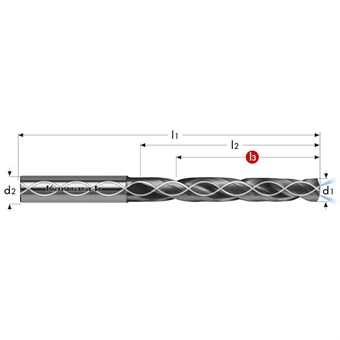

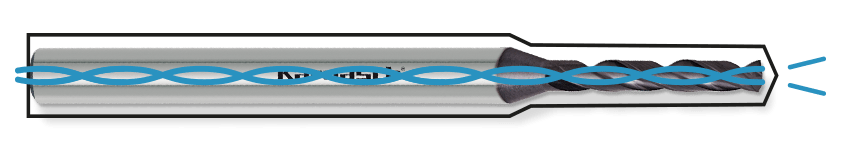

Twist Cooling

Advantages:

- Longer tool life

- Better chip removal

- Higher cutting speeds

- Process-reliable drilling

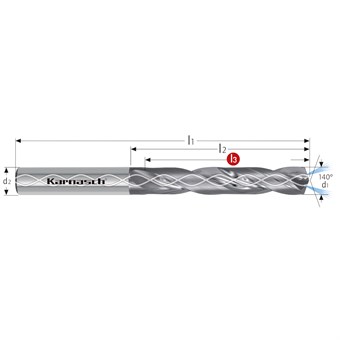

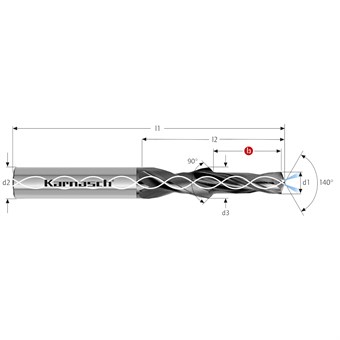

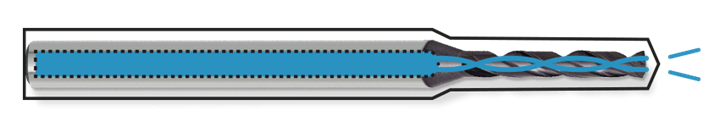

Power Chamber Shank

Advantages:

- Longer tool life

- Increased coolant leak at the same pressure but also at low pressure

- Better chip removal

- Higher cutting speeds

- Process-reliable drilling

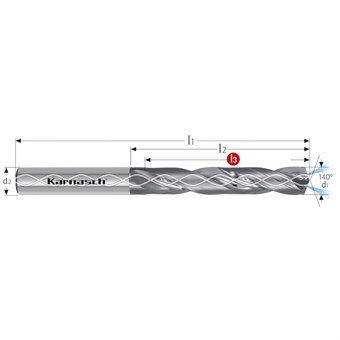

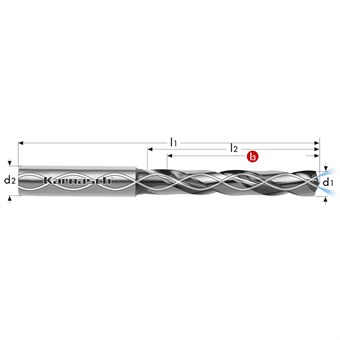

Drills with internal cooling for optimal cooling and lubrication

Maximum resilience for challenging applications.

Karnasch internal cooling guarantees optimal cooling results and presents obvious advantages as compared to external cooling. On the one hand, the cooling of the cutting edge can individually be optimized, with the result that the heat development is considerably reduced. The special power chamber by Karnasch ensures an increased coolant leak - at the same pressure but also at low pressure. On the other hand, Karnasch internal cooling removes the chips more efficiently and improves the overall cutting performance significantly. In addition to higher productivity, Karnasch internal cooling enhances tool lives and prevents premature tool breaking, which in turn leads to considerable cost savings.Advantages of the Karnasch cooling channel drills:

- Optimal tool life even under highest loads (optimal cooling and lubricating effect)

- Increased drilling speed

- Chips are more easily removed from the drilling range