Threading

The production of threads is one of the last steps in a workpiece's machining process. The right choice of tool is essential to eliminate the risk of damaging or destroying a component. Our new category offers specific solutions for drilling, milling or whirling threads for you. With our focus on quality and tool life, our tools support you with their process reliability when machining workpieces and components.Accurate threads for the highest demands

The production of threads is one of the last steps in a workpiece's machining process. The right choice of tool is essential to eliminate the risk of damaging or destroying a component.

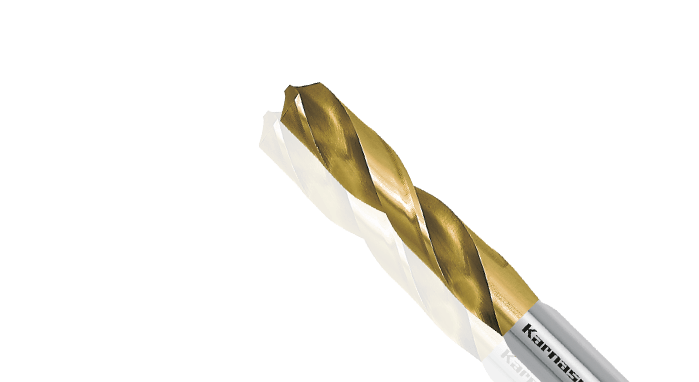

Our new category offers specific solutions for drilling, milling or whirling threads for you. With our focus on quality and tool life, our tools support you with their process reliability when machining workpieces and components.

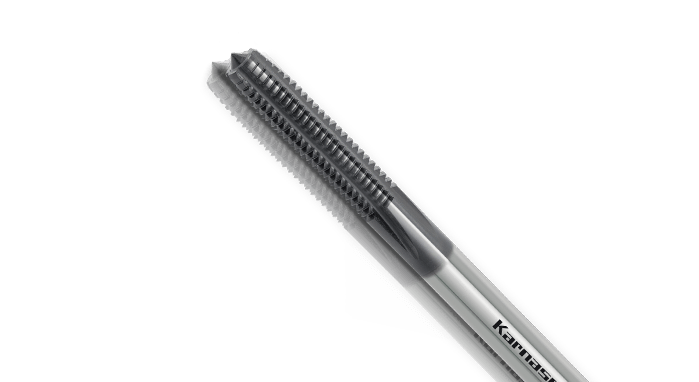

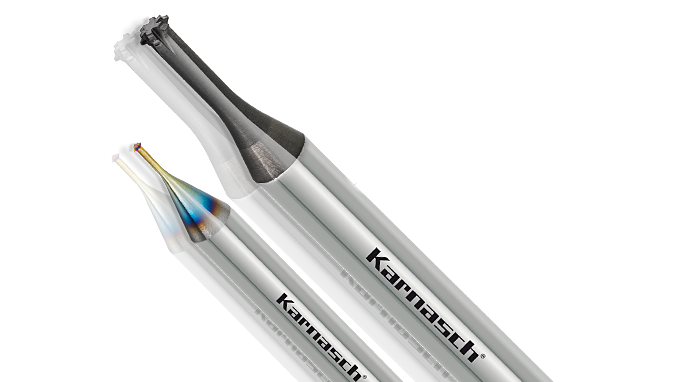

Our assortment ranges from solid carbide whirling thread cutters and thread mills to taps specifically for high-precision demands on all materials.

Be it blind holes or through holes, metric ISO threads or UNC/UNF threads - you will find the perfect solution within our product range. Our tools have been developed for our customers who need to meet highest demands in quality and machining results.

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now