Micro Tools

Karnasch Professional Tools is one of the world's largest microtool manufacturers for micro machining with a comprehensive range of microtools for all the needs of machining all steel materials, non-ferrous metals, stainless steels, laminates, plastics, cast iron and exotic materials. High speed cutting microtools for micro machining in worldwide unique microtool quality for metalworking of steel, graphite, stainless steel, copper, titanium, cast iron, gray cast iron, non-ferrous metals, aluminum, gold as well as composites and plastics.Precise microtools for your products of tomorrow

Karnasch microtools are a reliable partner for the most demanding machining requirements in series production.

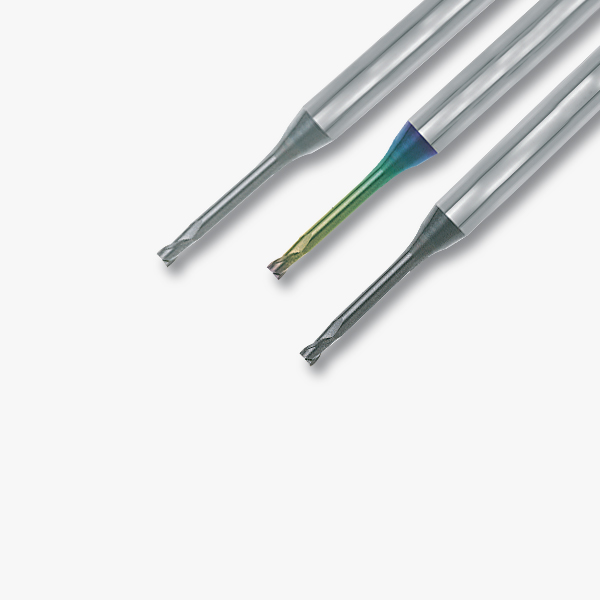

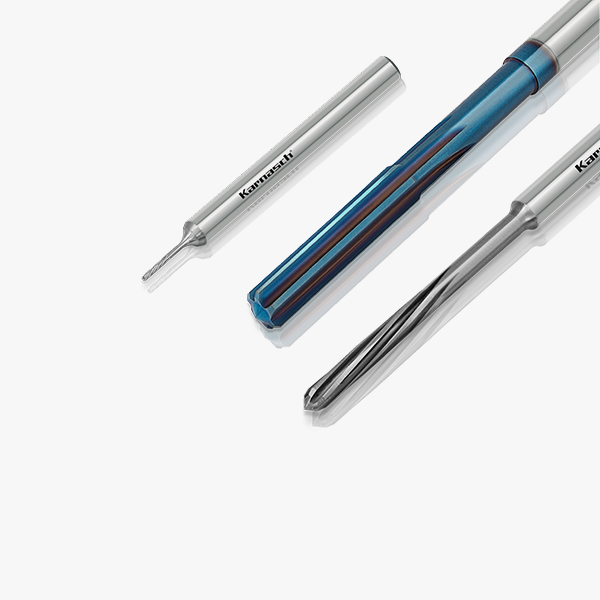

The range includes solid carbide micro cutters, solid carbide micro drills, solid carbide micro reamers and solid carbide micro whirling thread cutters, solid carbide deburrers and solid carbide drills for cutting all materials, available in numerous diameters, lengths, designs and in stock.

Microtools - for precision accurate to the µ

High speed cutting microtools for micro machining in worldwide unique microtool quality for metalworking of steel, graphite, stainless steel, copper, titanium, cast iron, gray cast iron, non-ferrous metals, aluminum, gold as well as composites and plastics.

Karnasch Professional Tools is one of the world's largest microtool manufacturers for micro machining with a comprehensive range of microtools for all the needs of machining all steel materials, non-ferrous metals, stainless steels, laminates, plastics, cast iron and exotic materials.

Intensive developments and many years of expertise in microtool technology have resulted in technically sophisticated product series which are characterized by excellent performance features and high-precision engineering tolerances. This outstanding microtool quality is available in stock and, regarding its entire product range, worldwide unique in this form.

Karnasch microtools (above all micro cutters and micro drills) are used in serial production in CNC centers and industries such as automobile industry, aerospace and aerocraft industry, die and mold construction, fine mechanics, electronics production, jewelry and watchmaking industry, dental industry, medical engineering and prototype construction.

CHARACTERISTICS OF MICRO CUTTERS:

- A comprehensive range of microtools from Ø 0.05 mm

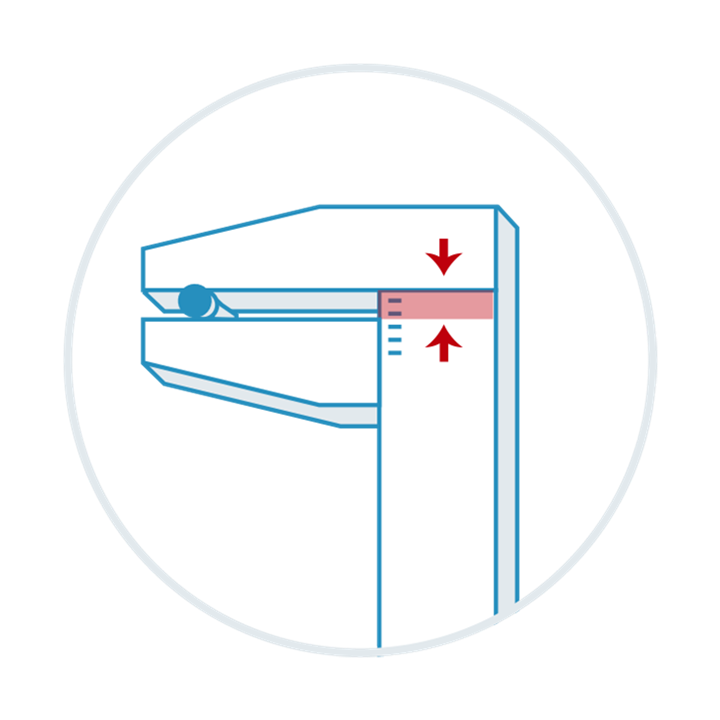

- Different tool geometries and cutting edge preparations suitable for the every application

- Specially adjusted tool coatingsBest carbide materials

- Process-reliable machining for numerous applications

- Radius accuracy: +/- 0.002 mm

- Concentricity accuracy: 0.002 mm

- Diameter tolerance: 0/-0.010 mm

CHARACTERISTICS OF MICRO DRILLS:

- Comprehensive range of microtools from Ø 0.1 mm

- With internal cooling from Ø 0.8 mm

- Specially adjusted tool coatings

- Best carbide materials

- Process-reliable machining for numerous applications

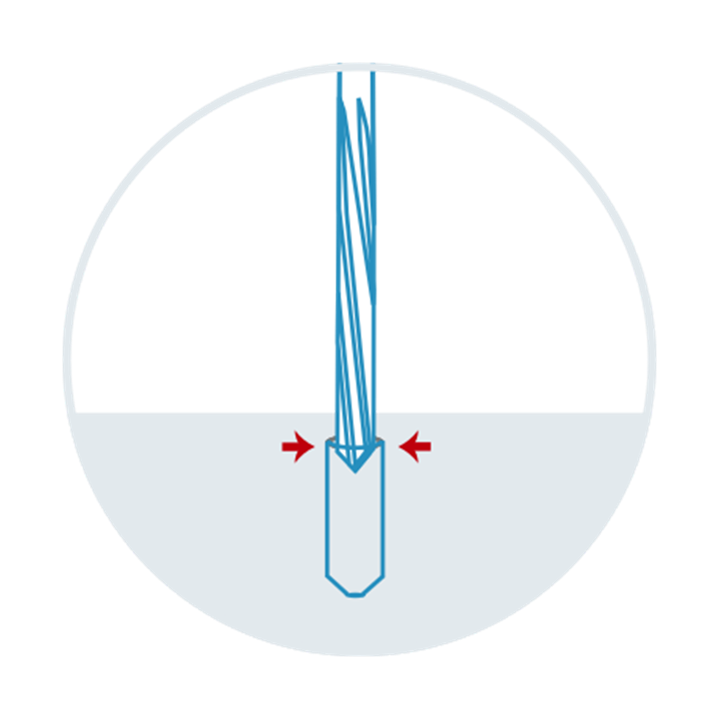

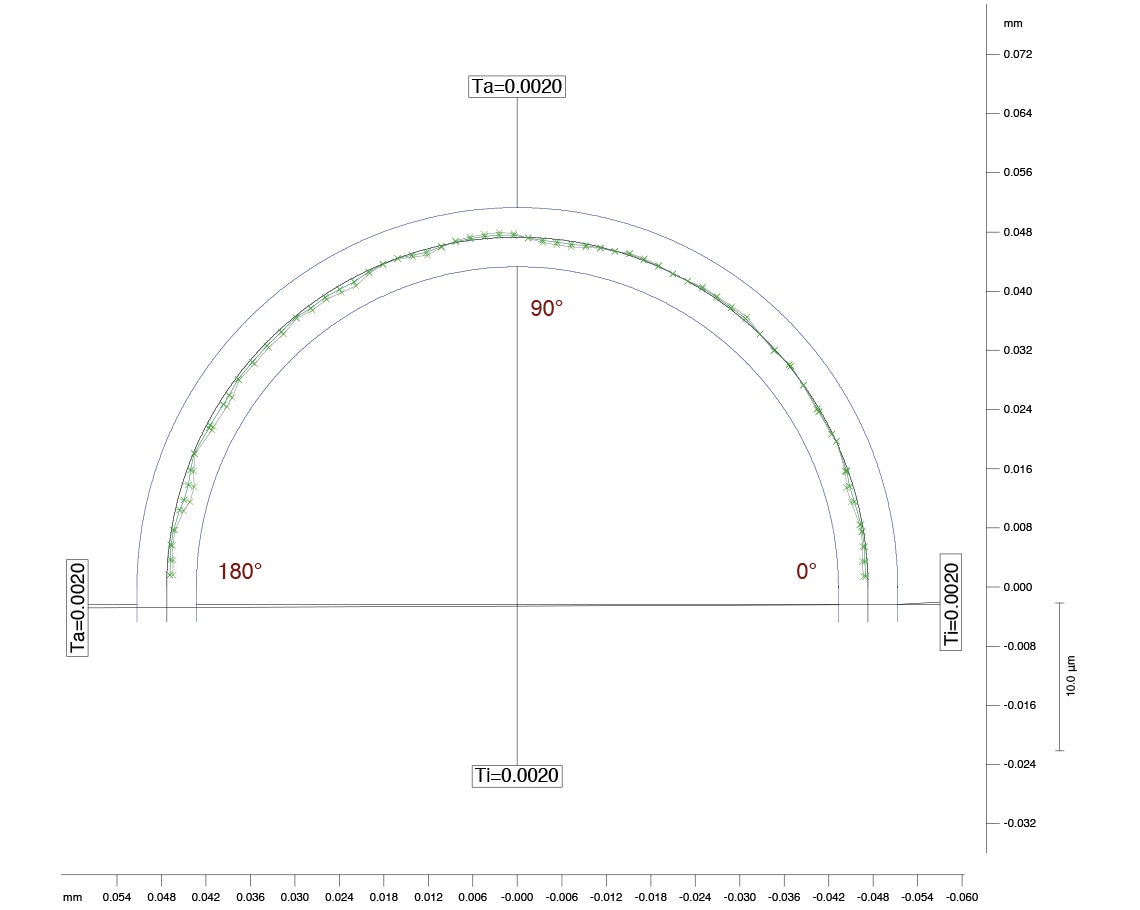

REPRESENTATION OF THE RADIUS CONTOUR OF KARNASCH MICRO CUTTERS

Max. deviation inside | Tolerance exceedance inside |

0.8 µm | |

Max. deviation outside | Tolerance exceedance outside |

0.4 µm | -1.6 µm |

Rotation | Number of actual points |

0.0000° | 67 |

Diff.-X | Surface |

0.0 µm | 0.003 mm2 |

Diff.-Y | Diameter coextensive circle |

0.0 µm | 65.2 µm |

One-pass strategy | Mirroring |

BestFit | + |