Solid Carbide Thread Cutters

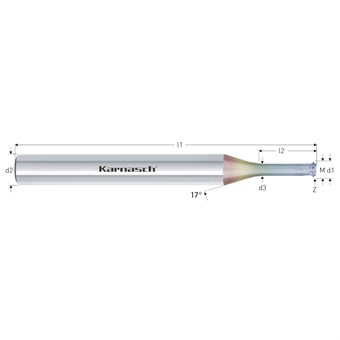

Premium-quality solid carbide whirling thread cutters with logarithmic relief grinding for metalworking up to 70 HRC, non-ferrous materials and graphite as well as for metric internal threads, without burr formation for better tool life.The high speed cutting solid carbide whirling thread cutters by Karnasch in premium quality

Small in detail, great in performance. For the metal machining of aluminum, copper, steel, as well as GRP/CRP, graphite and plastics.

The Karnasch tool series of solid carbide whirling thread cutters is designed for the demanding requirements for thread milling. It offers precise results without burr formation when cutting thread tapping drill holes into materials that are difficult to machine.

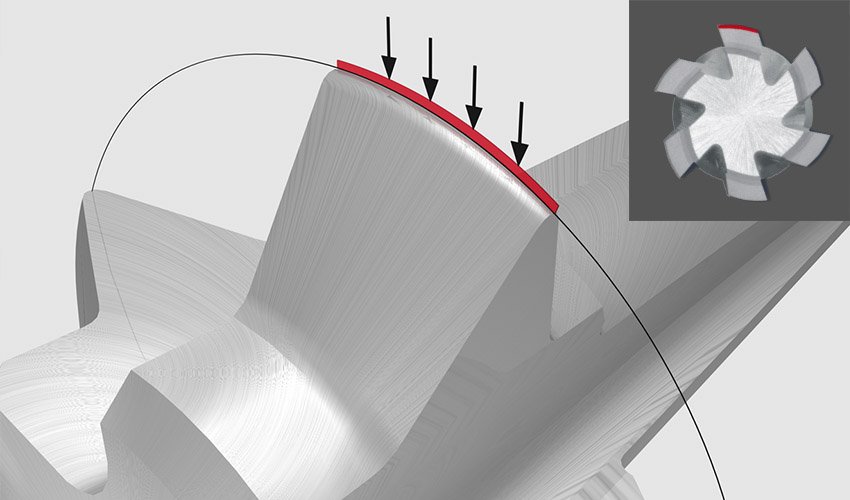

Due to the logarithmic relief grinding, the solid carbide whirling thread cutters achieve considerable improvements of tool lives. In addition, the rake angle and relief ground remain stable, which increases process reliability. With adjusted tool coatings, you achieve a consequent increase in productivity in metal cutting.

The Karnasch solid carbide whirling thread cutters are our solutions for the steadily growing challenges of our customers and for the high expectations of our tools' quality and machining results.

1 3 Results

The new standard for threading with whirling thread cutters

The solid carbide whirling thread cutters by Karnasch for threading in steel have a specially adjusted tool coating that contributes to an excellent surface finish and an outstanding wear resistance.Due to the special profile shape the thread remains true to size, distortion-free and is shaped optimally.

The process reliable chip removal is controlled by especially developed cutting edge geometries. The internal coolant supply and the cooling channel outlets at each cutting edge increase process reliability and service life considerably.

The Karnasch range of threading tools includes not only solid carbide whirling thread cutters but also solid carbide thread cutters, solid carbide taps and HSS-Co taps.

The Karnasch range of solid carbide thread whirling cutters offers the following advantages:

- Can be used for machining carbide up to 80 HRC

- Logarithmic relief grinding

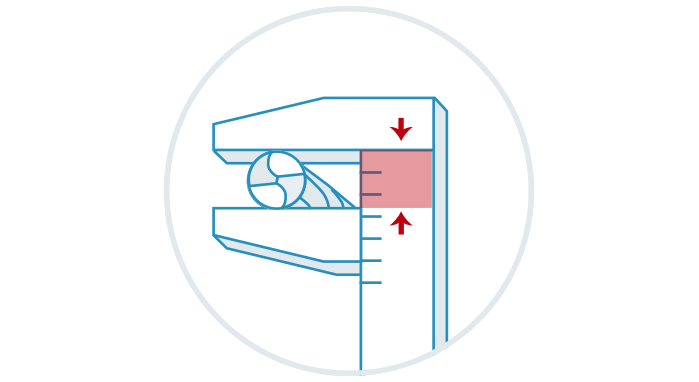

- Machining of internal threads (internal whirling)

- No degree formation because of overlapping

- Special tool coatings for machining various materials

- Standard dimensions available in stock