Composite Tools

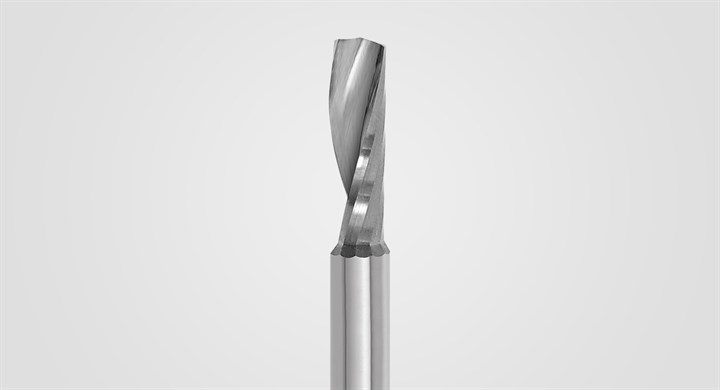

The Karnasch composite tool range offers versatile solutions for composite materials that are difficult to machine. Karnasch solid carbide composite tools have been specially developed for machining of materials such as aluminum, GRP/CRP, graphite, acrylic, titanium, honey comp and FR4. One of the latest developments are CVD (chemical vapour deposition) end mills, which have revolutionized the machining of materials in the aerospace and automobile industries.Composite tools by Karnasch are the future in machining of fiber composite materials

Karnasch's high speed cutting composite tool range includes solid carbide end mills, CVD end mills, PCD end mills, MKD end mills as well as solid carbide drills, PCD drills, spade drills and PCD saw blades. Our composite tools are suitable for 3D copy milling, contour milling, face and step milling, tapping, drilling, circumference cutting, deburring, slot cutting, countersinking and sawing.

The Karnasch composite tool range offers versatile solutions for composite materials that are difficult to machine. Karnasch solid carbide composite tools have been specially developed for machining of materials such as aluminum, GRP/CRP, graphite, acrylic, titanium, honey comp and FR4.

One of the latest developments are CVD (chemical vapour deposition) end mills, which have revolutionized the machining of materials in the aerospace and automobile industries. These composite tools are extremely sharp due to their laser-cut cutting edges and ensure a smooth cut with a high-precision cutting tolerance of up to 1µ.

This increases tool lives by up to 300%, prevents delamination and produces very smooth surfaces. Due to special geometries, drilling without cut-outs in GRP/CRP is no problem for Karnasch composite tools.

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now

Shop Now

THE SPECIAL CHARACTERISTICS OF KARNASCH COMPOSITE TOOLS:

- No delamination

- High surface finish quality

- Special geometries to avoid vibrations at great working depths

- Narrowest product tolerances

- Highest tool lives

- No cut-outs

- Balanced up to < 60,000 rpm

- 100% quality control

Karnasch composite tools - the specialists in machining of fiber composite materials

The composite tools by Karnasch are optimally designed for the requirements of the machining of fiber composite materials. They achieve best results in terms of tool life, surface finish and cutting quality. In order to meet the high variety of different materials in the field of composite tools, various product families were developed.These composite solid carbide end mills and solid carbide drills are adjusted to the specific applications and materials by special geometries and tool coatings.