Tools For Graphite

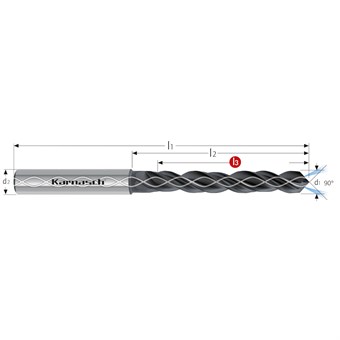

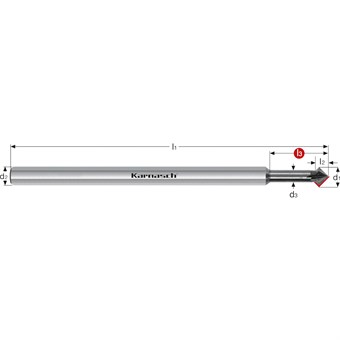

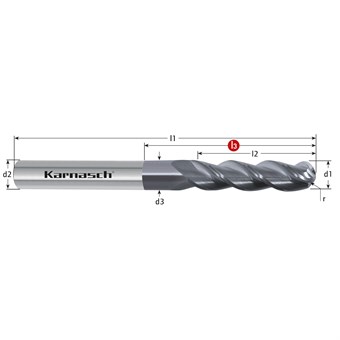

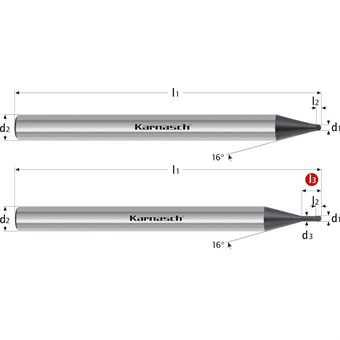

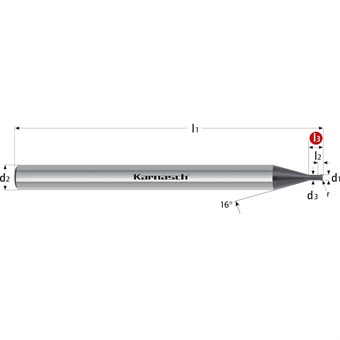

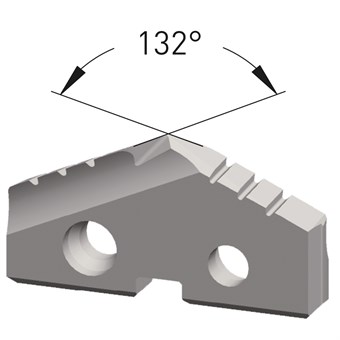

Karnasch has developed an individual range of tools for any challenges of graphite machining. In addition to solid carbide end mills, solid carbide drills, solid carbide taps, whirling thread cutters, solid carbide thread mills and solid carbide deburrers, our microtools are also available for processing up to the very finest detail.Karnasch solid carbide end mills, drills, threads, whirling thread cutters and deburrers for graphite machining

Exceptional precision and performance in graphite machining - narrowest production tolerances, highest concentricity and maximum tool life can be achieved with graphite tools by Karnasch.

Karnasch has developed an individual range of graphite tools for any challenges of graphite machining. In addition to solid carbide end mills, solid carbide drills, solid carbide taps, whirling thread cutters, solid carbide thread mills and solid carbide deburrers, our microtools are also available for processing up to the very finest detail. The graphite tools by Karnasch convince with their nanocrystalline diamond tool coating in accuracy, tool life and the worldwide unique engineering tolerance.

Graphite electrodes are becoming increasingly important in modern tool and mold making. Graphite is also used more and more in machinery and plant engineering as well as in medical technology. The highly abrasive material is being processed into more filigree shapes, increasing the challenges for the tool industry.

Advantages of Karnasch graphite tools

The Karnasch program of graphite tools includes corner radius end mills, full radius end mills, rough end mills as well as solid carbide drills, thread mills, whirling thread cutters and deburrers and thus offers one of the most extensive programs of diamond coated tools for graphite machining.

Applications:

- Milling and drilling of graphite

- Milling and drilling of electrodes

- Deburring of graphite

- Thread milling in graphite