- Home

- |

- Newsletters

- |

- Production of a die mould

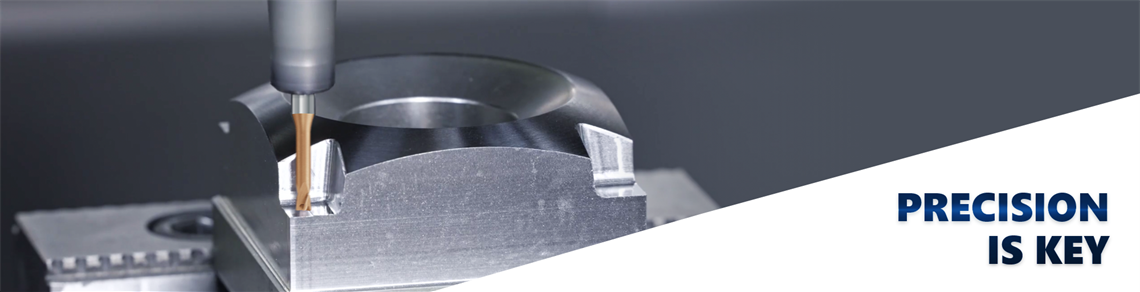

See our end mills in action

Our premium quality CNC milling tool range features high precision end mills that will significantly improve your finishes across a wide range of materials. With their unique and innovative geometry, you are guaranteed consistent high quality results and process reliability. Available in numerous milling depths, designs and diameters from 0.05 mm.

Below you can see a selection of our End Mills in action in the various production stages of a single die made from hardened steel. The process is broken down into easy to follow and informative steps that include roughing, high feed milling and finishing.

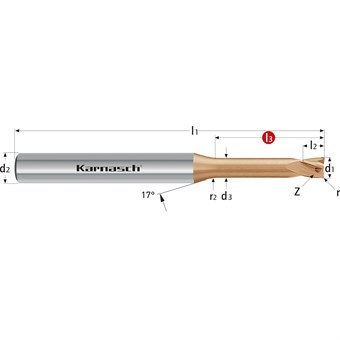

Solid Carbide High Feed Finishing End Mill

Art. 30.6278 (10mm)

Helical plunging into the full solid material 1.2379 63 HRC. Previous pre-machining processes such as pre-milling, annealing and hardening are no longer necessary.

Cutting Data

Vc = 78 m/min

Vf = 2,850 mm/min

N = 2,500 1/min

Ap = Helix 0.6°

Fz = 0.19 mm

Ae = 5 mm

HHC Solid Carbide End Mill

Art. 30.6456 (10mm)

Pre-machining and finish machining of outer contours and center bore to finished size. Direct finishing without any material allowance.

Cutting Data

Vc = 107 m/min

Vf = 920 mm/min

N = 3,406 1/min

Ap = 25 mm

Fz = 0.045 mm

Ae = 0.17 mm

Solid Carbide High Feed Finishing End Mill

Art. 30.6278 (10mm)

Pre-machining of two mould draft angles and four guide corners in the die structure of the part. Preparation of the workpiece for further machining processes with smaller end mills without reclamping of the workpiece.

Cutting Data

Vc = 78 m/min

Vf = 2,850 mm/min

N = 2,500 1/min

Ap = 0.3 mm

Fz = 0.19 mm

Ae = 4 mm

Solid Carbide High Feed Finishing End Mill

Art. 30.6278 (2mm)

Roughing and semi-finishing process of two of four guide corners by using high feed technology.

Short Solid Carbide End Mill with Corner Radius

Art. 30.6267 (2mm)

Roughing and semi finishing two of four guide corners by using SolidCAM's iMachining technology.

Cutting Data

Vc = 105 m/min

Vf = 1,530 mm/min

N = 16,700 1/min

Ap = 1.5 mm

Fz = 0.023 mm

Ae = 0.02 mm

iMaching strategy

Solid Carbide 3D Ball Nose End Mill, Rockwell Cutter

Art. 30.6486 (2mm)

Pre-machining and finishing of the inner conical surface in one helix operation. Demonstration of conventional 3-axis machining with small tools and infeeds.

Cutting Data

Vc = 110 m/min

Vf = 2,800 mm/min

N = 17,500 1/min

Ap = 0.05 - 0.15 mm

Fz = 0.04 mm

Ae = 0.05 mm

Solid Carbide High Efficient Finishing Parabola End Mill

Art. 30.6276 (2mm)

Pre-machining and finishing of the outer conical surface in a spiralised movement. When compared with small ball nose end mills, you get higher infeeds and faster processing and even much better surface finishes.

Cutting Data

Vc = 77 m/min

Vf = 1,400 mm/min

N = 7,000 1/min

Ap = 0.32 mm

Fz = 0.05 mm

Ae = 0.2 mm

Short Solid Carbide End Mill with Corner Radius, Rockwell Cutter

Art. 30.6267 (2mm)

Finishing of the three guide surfaces on the sidewalls and bottom of two of four guide corners. Presentation of the conventional 3-axis machining with small tools and infeeds. Separation of the sidewalls machining and bottom machining.

Solid Carbide 3D Ball Nose End Mill, Rockwell Cutter

Art. 30.6486 (2mm)

Finishing of the three guide surfaces on the sidewalls and bottom of two of four guide corners. Presentation of 5-axis machining, sidewalls and bottom machining processes are no longer separated.